- Joined

- Feb 1, 2015

- Messages

- 9,948

About a year ago, I needed to modify some 3/8 brass bolts by making domed heads instead of the hex. I looked into the commercial offerings as well as some of the home brewed and decided it was simpler to use the CNC mill as a vertical CNC lathe. And decided to go that route.

Inspired by a recent post by randyc, I decided to look into the possibility of spherical turning on my G0602 lathe again. I found that Randy was indeed correct; I could not find a configuration where I could use either my QCTP or the OEM tool post to turn convex curves.

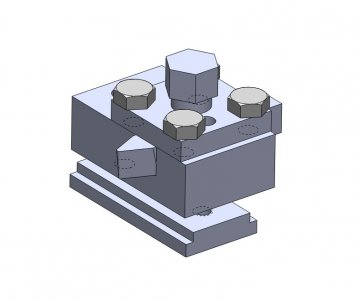

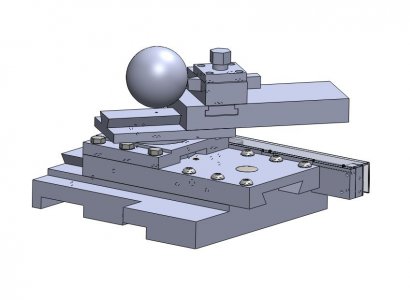

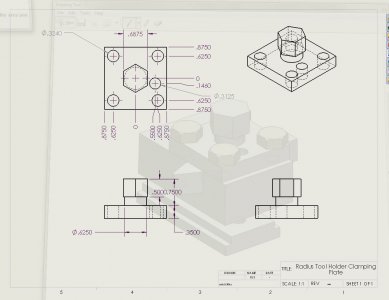

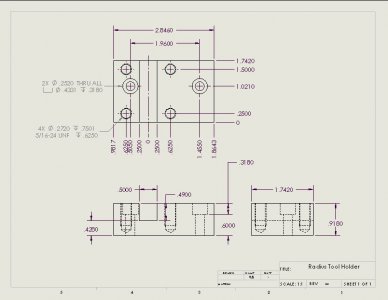

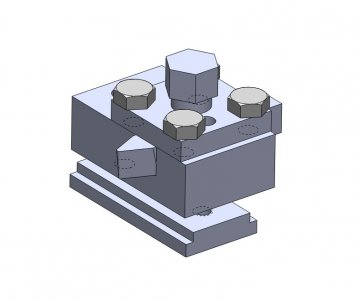

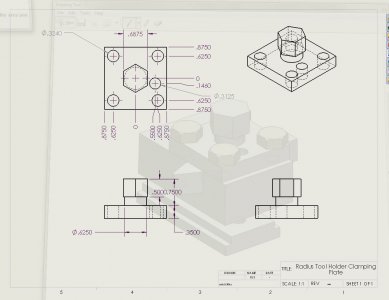

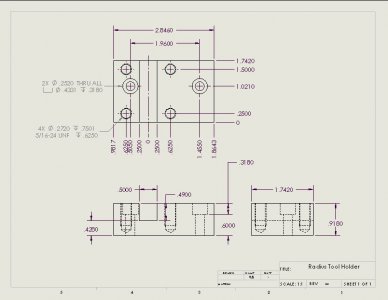

I set about designing a tool post specifically for turning radii, using the Tee nut from the OEM tool post. The resultant tool post takes a 1/2 inch lathe tool and it is capable of turning a 2-1/8" ball. With a 1/2 tool, the bit is aligned vertically with the spindle axis. The tool bit is offset to the left to permit turning the lower half of the sphere. When using the 6" three jaw, the ball has to protrude about 3" to prevent the compound from hitting the chuck jaws. If a 5C collet chuck were used, that distance could be shortened considerably.

Rotation is about the boss on the compound and its mating hole in the cross feed. Rotation is controlled by a 11/16" hex head stud on the tool clamp driven by a 3/8" breaker bar and socket. The hex stud works well with the breaker bar but will also work with a box wrench or a socket with ratchet.

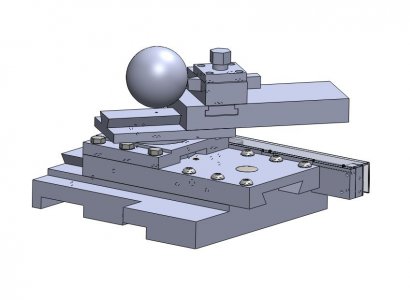

One problem that I ran into is that the lead screw on the G0602 is not long enough to reach the centerline of the lathe as is required for turning a ball. Making a lead screw with an additional inch of travel was contemplated but discarded in favor of making a second mounting location on the cross slide.

I have a custom mounting clamp for the compound, patterned after a number of designs found on line. It is made from 5/8" plate and has six bolt holes rather than the two holes on the OEM version. Details may be found in a post on the Grizzly Industrial Inc. forum A set of mounting and locating holes were added to the rear of the cross feed slide to accommodate that clamp.

The auxiliary position now permits a total travel of the cross slide of more than 11" which has the benefit of permitting turning from the back side of the lathe which I had found useful in the past. The extra mounting holes are closed with set screws to prevent turning from lodging in them. I made a plug to fit the unused hole for the compound boss as well. I had to relocate the center oil port as well.

Centering the pivot point is relatively easy. Centering is done with the cross feed. A trial cut is made to start forming the sphere. This is done at a larger radius than the finished radius. When properly centered, the tool bit just grazes the cut surface when the tool is rotated to the back side of the ball. Once the center of the pivot point is established the cross slide is locked. The diameter is controlled with the compound feed. Because the tool bit is offset to the left, a .001" compound feed results in less than a .001" reduction in diameter. You can do the math to calculate exactly what the relationship is but it is just as easy to do a couple of trial cuts and measure.

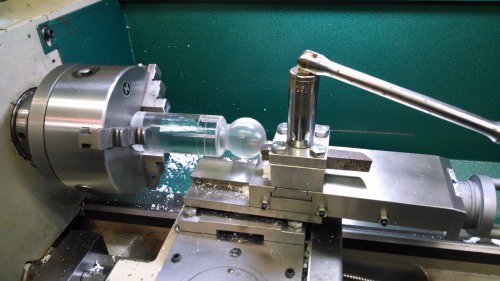

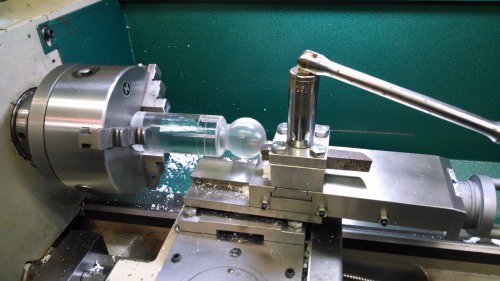

The first attempt at turning was a 1-1/2" ball from acrylic. I used a 1/2" tool bit from my collection, not attempting to grind a proper bit. The turning process went smoothly and was well controlled. It helps to tighten the clamp bolts lightly so there is a small amount of resistance. Do not overtighten as a jerky motion may result. Some way oil on the rotating surface also helps to smooth the motion.

Inspired by a recent post by randyc, I decided to look into the possibility of spherical turning on my G0602 lathe again. I found that Randy was indeed correct; I could not find a configuration where I could use either my QCTP or the OEM tool post to turn convex curves.

I set about designing a tool post specifically for turning radii, using the Tee nut from the OEM tool post. The resultant tool post takes a 1/2 inch lathe tool and it is capable of turning a 2-1/8" ball. With a 1/2 tool, the bit is aligned vertically with the spindle axis. The tool bit is offset to the left to permit turning the lower half of the sphere. When using the 6" three jaw, the ball has to protrude about 3" to prevent the compound from hitting the chuck jaws. If a 5C collet chuck were used, that distance could be shortened considerably.

Rotation is about the boss on the compound and its mating hole in the cross feed. Rotation is controlled by a 11/16" hex head stud on the tool clamp driven by a 3/8" breaker bar and socket. The hex stud works well with the breaker bar but will also work with a box wrench or a socket with ratchet.

One problem that I ran into is that the lead screw on the G0602 is not long enough to reach the centerline of the lathe as is required for turning a ball. Making a lead screw with an additional inch of travel was contemplated but discarded in favor of making a second mounting location on the cross slide.

I have a custom mounting clamp for the compound, patterned after a number of designs found on line. It is made from 5/8" plate and has six bolt holes rather than the two holes on the OEM version. Details may be found in a post on the Grizzly Industrial Inc. forum A set of mounting and locating holes were added to the rear of the cross feed slide to accommodate that clamp.

The auxiliary position now permits a total travel of the cross slide of more than 11" which has the benefit of permitting turning from the back side of the lathe which I had found useful in the past. The extra mounting holes are closed with set screws to prevent turning from lodging in them. I made a plug to fit the unused hole for the compound boss as well. I had to relocate the center oil port as well.

Centering the pivot point is relatively easy. Centering is done with the cross feed. A trial cut is made to start forming the sphere. This is done at a larger radius than the finished radius. When properly centered, the tool bit just grazes the cut surface when the tool is rotated to the back side of the ball. Once the center of the pivot point is established the cross slide is locked. The diameter is controlled with the compound feed. Because the tool bit is offset to the left, a .001" compound feed results in less than a .001" reduction in diameter. You can do the math to calculate exactly what the relationship is but it is just as easy to do a couple of trial cuts and measure.

The first attempt at turning was a 1-1/2" ball from acrylic. I used a 1/2" tool bit from my collection, not attempting to grind a proper bit. The turning process went smoothly and was well controlled. It helps to tighten the clamp bolts lightly so there is a small amount of resistance. Do not overtighten as a jerky motion may result. Some way oil on the rotating surface also helps to smooth the motion.