- Joined

- Aug 19, 2013

- Messages

- 764

Was it sitting in an Art School?

Great find anyway, good luck with it !

Hey, I went to an art school (Industrial Design). We had a '64 virgin 9A SB under drive. SB GREY ALL THE WAY.

Was it sitting in an Art School?

Great find anyway, good luck with it !

Sorry forgot you guys can't read minds haha I've done some very basic tests with the limited equipment I have on hand and torn into the gear box to assess the damage will post results soon!You need to provide more information. Are the bed ways worn ? Hard to tell from a photo . The swarth on the carriage just needs a clean up, give it a good soaking in kero . If the bed is not worn then you have a great lathe . Mike

I got a few things a face plate, a catch plate a box of HHS tools some large carbide tools a small 4 jaw chuck another face plate from i dont know what nothing super exciteingI'd say soak it too. Clean her up real good re oil everything . After the paint job of course, what color are YA gonna pick ? SAFTEY orange with reflected strips. Or a good pine green even gray blue tinted . She looks in good shape for a school machine. Did YA score any other chucks or collets. The Orange is a jab for its multi colors. I've seen some loud colors on some tho. Good luck on the LATHE YA know you practically stole it for that money. Keep us in the loop on progress and or problems. Thanks

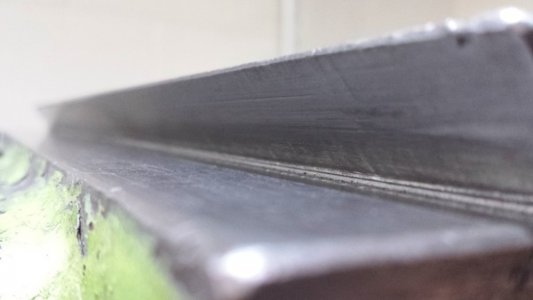

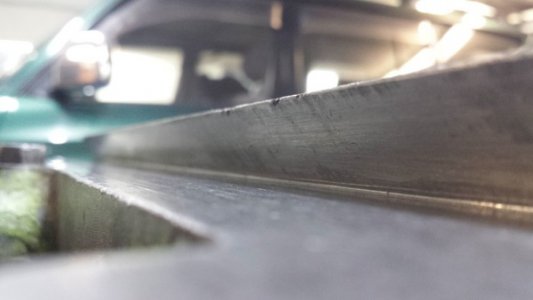

A few comments. The bed looks OK to me , that tiny bit of wear is nothing to worry about .

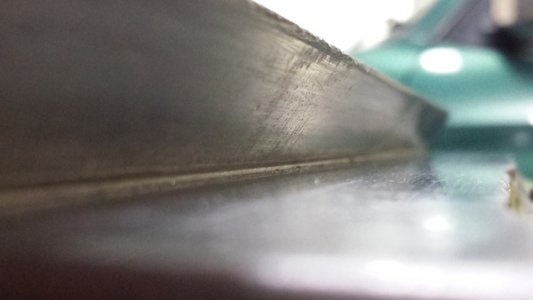

The cross slide looks a bit the worse for wear but again , it is probably useable as it is . The cross slide nut will be worn but thats not a disaster either .

You might ask G&M tools for a new shaft , they are in the UK, they bought the old Harrison works spares , they have bits on EBAY . . There is a guy in NZ who has L5 parts on EBAY . Have you seen this kiwi guy with L5 bits ?

http://www.ebay.com.au/itm/Lathe-Ha...710095?hash=item1c6ed7a34f:g:OrkAAOSw9IpXzkNn

I bought a L5 fixed steady from him . One thing that annoys me about the early L5's is the small bore of the spindle, it is only 7/8" .

The later L5's from the mid 1950's on had a hardened bed .