Nice job! Did you pick up a set of magnetic bases for mounting the rest, like Harold does in his video? Looks like a great idea.

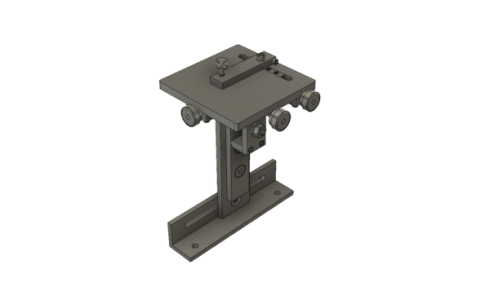

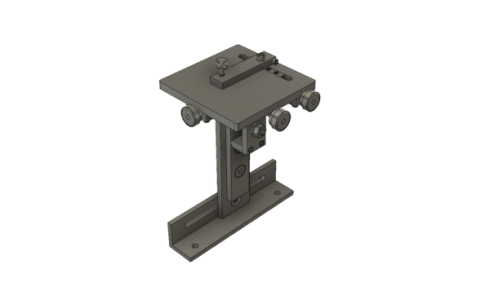

I have 5 of Harold's books and visit his website frequently. He's an ingenious person and I'm amazed at the designs he comes up with. I've already made a few of his tools; the lining tool, his end mill sharpening fixture (ends only), slitting saw sharpening jig and I'm currently about 3/4 of the way through completion of his end mill sharpening jig (for both the ends and flutes). After completion of the end mill jig I was going to start on the complex grinding rest but have now changed my mind and will go with the simpler one as you did.

I did the same as you and converted all hole sizes and threading to imperial sizes. But did it in pencil on the drawings in the book. Computer would be much better method. Wish I could get my hands on an inexpensive metric drill index, then I wouldn't bother with the conversions.

What did you use for the 1" plastic ball and where did you get it? Does it need to be a hard plastic?