Hello everyone,

I recently acquired a used Harig 612 hand feed surface grinder. I believe this machine was manufactured somewhere in the 1990's. Unfortunately, my machine came with the rack and pinion table movement system. The rack and pinion works, and it certainly does the job, but I wasn't a fan of the bumpy feel when moving the table back and fourth. Luckily, Harig also offered a cable drive as an option. The cable drive is much smoother, and all of the attachment points were machined from the factory. I just needed to make/buy the parts to finish the job.

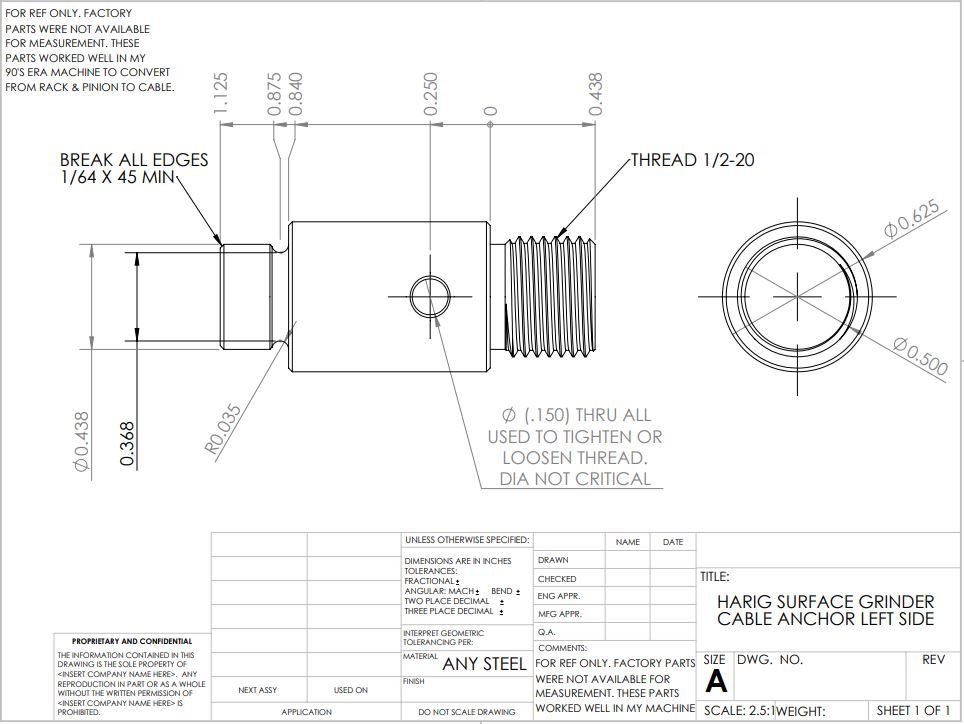

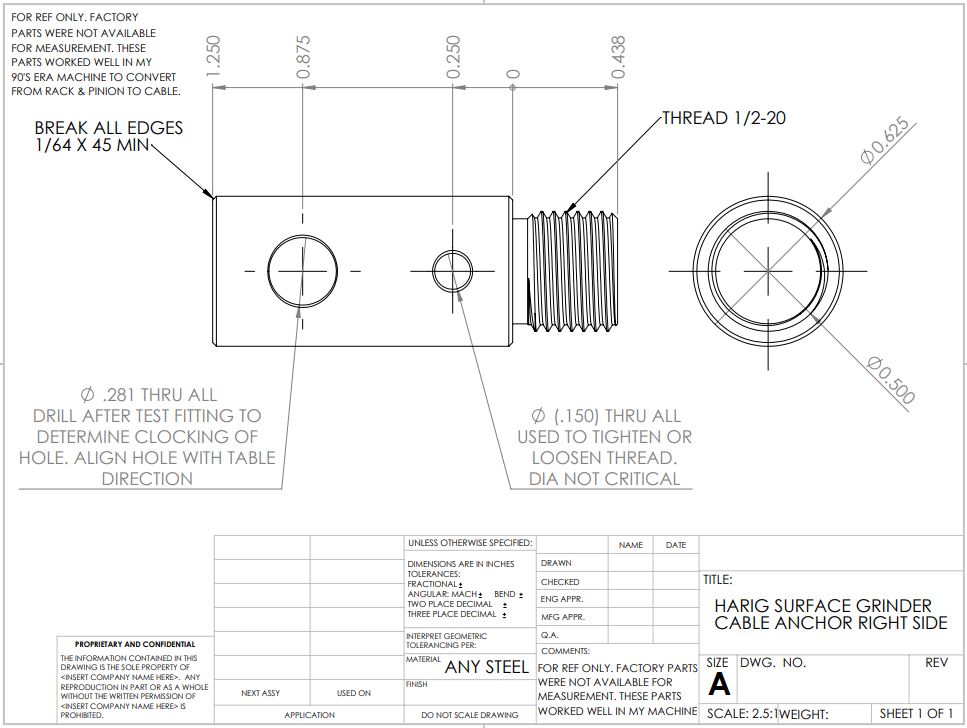

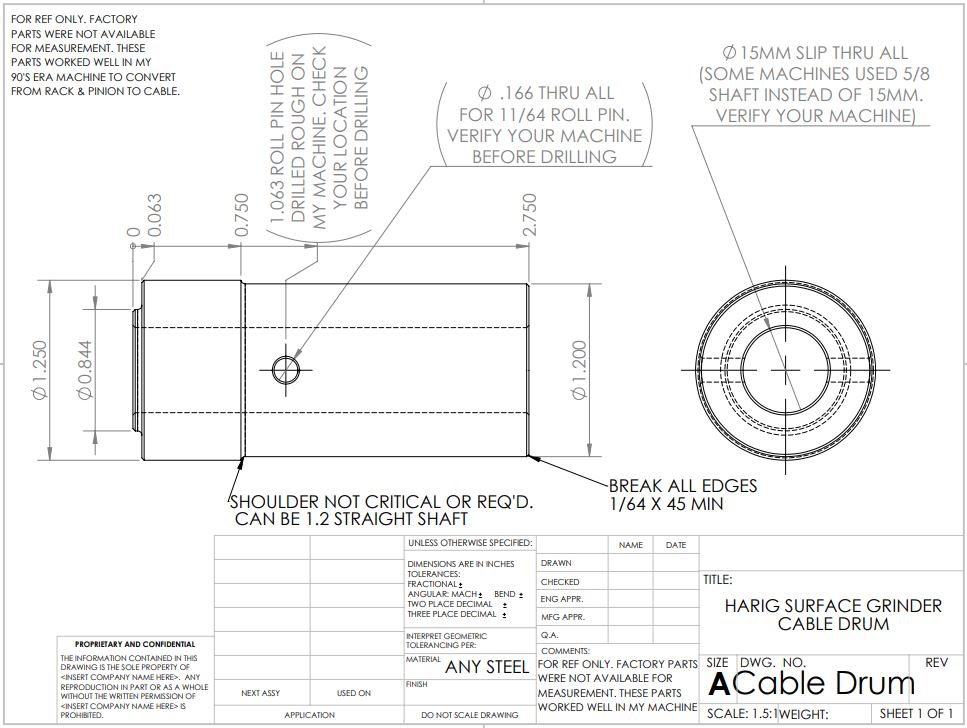

This is where @akjeff comes in. He recently saved a Harig that had been tipped over. His work turned out beautifully, and he documented the process on this forum. Make sure to look up "Saving a Harig Super 612". While looking through his post, I noticed that he needed to re-make many of the components that I needed to convert my machine to cable drive. After asking akjeff if he could provide some more information on these parts, he graciously provided many pictures, dimensions, and details of the job. With this information, I was able to re-make all of the parts needed and detail the job for people in the future to replicate. Akjeff's machine was slightly different than mine and I needed to come up with many of the dimensions based on pictures and measurements from my machine, but the parts that I machined worked great and I am very satisfied. With that in mind, please check your machine before using my drawings to ensure that these parts will work for your situation.

I purchased

-QTY 1- LONGITUDE FEED CABLE HARIG PARTS F/MODEL 612 $44.78 as of posting date. From MSCDIRECT. https://www.mscdirect.com/product/details/77013845

-QTY 1- National Hardware® 1/4" x 4" Zinc Eye Bolt with Nut $0.50 as of posting date. From Menards. https://www.menards.com/main/hardwa...ye-bolt-with-nut/n221-127/p-1444448915944.htm

I machined all the parts from steel I had laying around the shop. Any grade steel should work fine. After machining, I cold blued the parts in hopes of adding a small amount of corrosion prevention. I used a hacksaw to cut the eyebolt opening so the end of the cable loop could be slipped over it. Eyebolt type is not critical. I attempted to copy the original as close as possible at 1/4-20 X 4".

See my prints and pics below. The prints/models should cover any details that I may have missed in the post, but feel free to ask questions, copy, and or add input.

I recently acquired a used Harig 612 hand feed surface grinder. I believe this machine was manufactured somewhere in the 1990's. Unfortunately, my machine came with the rack and pinion table movement system. The rack and pinion works, and it certainly does the job, but I wasn't a fan of the bumpy feel when moving the table back and fourth. Luckily, Harig also offered a cable drive as an option. The cable drive is much smoother, and all of the attachment points were machined from the factory. I just needed to make/buy the parts to finish the job.

This is where @akjeff comes in. He recently saved a Harig that had been tipped over. His work turned out beautifully, and he documented the process on this forum. Make sure to look up "Saving a Harig Super 612". While looking through his post, I noticed that he needed to re-make many of the components that I needed to convert my machine to cable drive. After asking akjeff if he could provide some more information on these parts, he graciously provided many pictures, dimensions, and details of the job. With this information, I was able to re-make all of the parts needed and detail the job for people in the future to replicate. Akjeff's machine was slightly different than mine and I needed to come up with many of the dimensions based on pictures and measurements from my machine, but the parts that I machined worked great and I am very satisfied. With that in mind, please check your machine before using my drawings to ensure that these parts will work for your situation.

I purchased

-QTY 1- LONGITUDE FEED CABLE HARIG PARTS F/MODEL 612 $44.78 as of posting date. From MSCDIRECT. https://www.mscdirect.com/product/details/77013845

-QTY 1- National Hardware® 1/4" x 4" Zinc Eye Bolt with Nut $0.50 as of posting date. From Menards. https://www.menards.com/main/hardwa...ye-bolt-with-nut/n221-127/p-1444448915944.htm

I machined all the parts from steel I had laying around the shop. Any grade steel should work fine. After machining, I cold blued the parts in hopes of adding a small amount of corrosion prevention. I used a hacksaw to cut the eyebolt opening so the end of the cable loop could be slipped over it. Eyebolt type is not critical. I attempted to copy the original as close as possible at 1/4-20 X 4".

See my prints and pics below. The prints/models should cover any details that I may have missed in the post, but feel free to ask questions, copy, and or add input.