New Years Greetings.

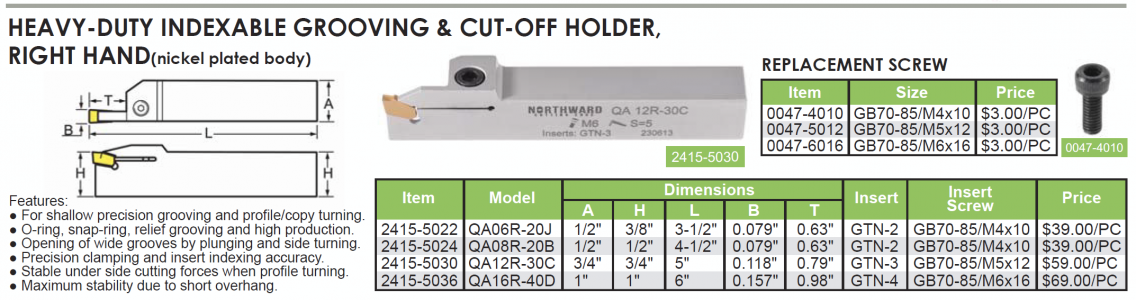

I have a recently acquired parting tool that I tried for the first time yesterday. It uses what I think are GTN series inserts. The tool says S=5 so I assume it is GTN 5. It came with one insert, well, ah...inserted.

When I began parting some 1045 it chattered like crazy at 90 RPM. So I got a little more aggressive with in feed and things went swimmingly until about 1/2" in the insert snapped without warning. Was using lube brushed on.

In looking for a replacement insert it quickly became obvious that the set of inserts that came with it are wrong- double ended.

So this is all a long way around to ask about the interchangeability of these inserts. When I looked up specs on the inserts they say that a No5 is .2" wide. The one I was using was nowhere near that wide. Are the inserts all the same dimensionally apart from the width? Can I use a No 3 insert? Or is that part of the reason that the original broke? The one that was in there is the same width as the tool where it is clamped in.

Obviously this is my first foray into bewildering world carbide part off tooling. I have always used HSS up until now with not too many interesting events. Seems to be calling back to my roots.

I have a recently acquired parting tool that I tried for the first time yesterday. It uses what I think are GTN series inserts. The tool says S=5 so I assume it is GTN 5. It came with one insert, well, ah...inserted.

When I began parting some 1045 it chattered like crazy at 90 RPM. So I got a little more aggressive with in feed and things went swimmingly until about 1/2" in the insert snapped without warning. Was using lube brushed on.

In looking for a replacement insert it quickly became obvious that the set of inserts that came with it are wrong- double ended.

So this is all a long way around to ask about the interchangeability of these inserts. When I looked up specs on the inserts they say that a No5 is .2" wide. The one I was using was nowhere near that wide. Are the inserts all the same dimensionally apart from the width? Can I use a No 3 insert? Or is that part of the reason that the original broke? The one that was in there is the same width as the tool where it is clamped in.

Obviously this is my first foray into bewildering world carbide part off tooling. I have always used HSS up until now with not too many interesting events. Seems to be calling back to my roots.