- Joined

- Feb 7, 2013

- Messages

- 792

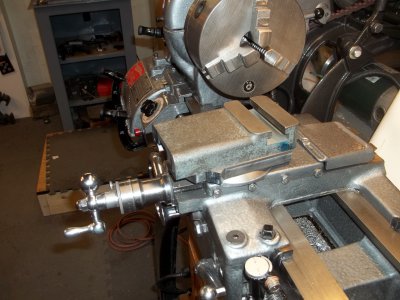

Yes there is no differance in transition between the two dove tails... I got this rotory table as a gift I tore it apart changed a bunch of stuff I did not like it works great.

http://www.grizzly.com/products/4-Rotary-Table-w-Indexing/H5940

- - - Updated - - -

Here is the thread. http://www.hobby-machinist.com/show...-H5940-Rotary-Table-rebuild?p=99640#post99640

http://www.grizzly.com/products/4-Rotary-Table-w-Indexing/H5940

- - - Updated - - -

Here is the thread. http://www.hobby-machinist.com/show...-H5940-Rotary-Table-rebuild?p=99640#post99640

Last edited: