- Joined

- Jan 22, 2014

- Messages

- 578

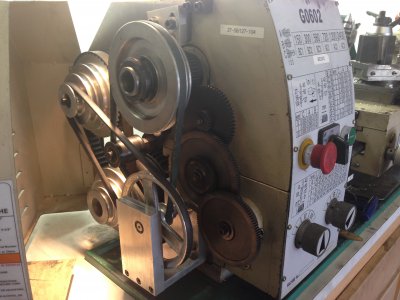

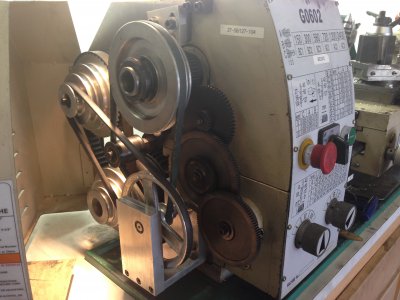

Since I’ve owned my Grizzly G0602 lathe, I’ve occasionally wished that I could slow the spindle speed down for certain operations. The lowest standard speed is 150 RPM and a little too fast for threading, turning and parting large diameters. Grizzly finally saw the need and the newer model (G0752) is equipped with a variable speed motor for an extra $450, and that’s a great thing. But for those of us that have the older models, we are stuck with only a couple of choices to slow these lathes down. The BEST way to do this and what some others have done is to set-up a variable speed drive system. Some have used DC tread mill motors and others have used AC frequency converters. Both require an electronic speed controller, a new motor and cost well over $300. I may still do this mod one day or upgrade my lathe, but for now I decided to take the “old school” approach because I did a lot of this when I worked in a prototype machine shop building industrial machinery.

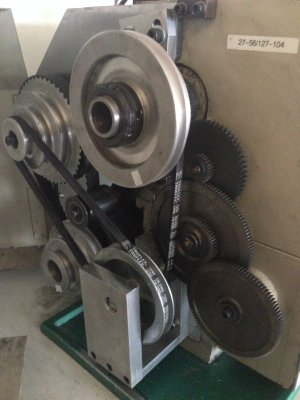

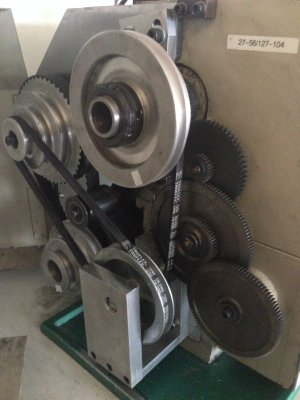

I was looking inside the cover of my lathe one day while making a speed change using my “Quick Belt Change” mod that I introduced to G0602 owners a few years ago (http://www.projectsinmetal.com/forum/general-discussion/diary-of-a-new-g0602). I found that there is still a bit of space where I could build and mount a custom, triple reduction jackshaft. I began measuring and calculating and found that with different combinations of pulleys another dozen speeds are entirely possible, but that’s not necessary.

I verified my spindle speed calculations with my digital tachometer and also found that the standard speeds from Grizzly are not accurate, I got 180, 320, 507, 795, 1284 and 2466. I then optimized the various pulley combinations using commonly available parts to fill the gap below Grizzly’s 150 RPM and I settled on the 3 most practical low-end speeds of 75, 105, 147 rpm.

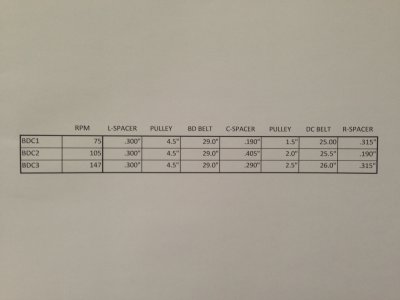

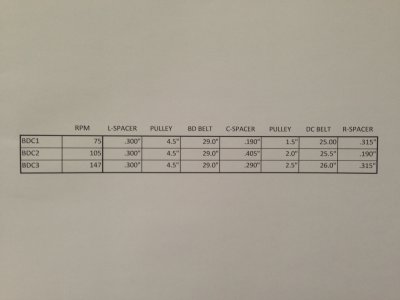

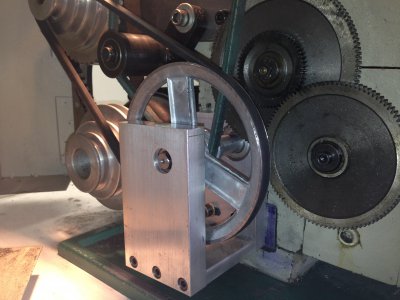

To use the 3rd reduction, you have to install the proper belt/pulley combination when you need it. It’s not difficult and takes only a couple of minute when used in combination with the “quick belt change” mod. I plan to only use it on rare occasions and take it off when not in use. I also developed this pulley/shaft spacer/belt/speed combination “cheat sheet” for quick reference to keep on the inside of the belt cover so I don’t have to remember what-goes-where when I need it.

I also modified a 5.5” pulley and was able to get 3 more lower speeds of 37, 60 and 80 rpm.

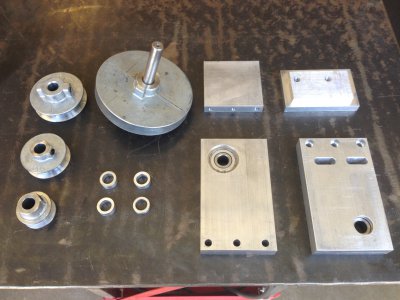

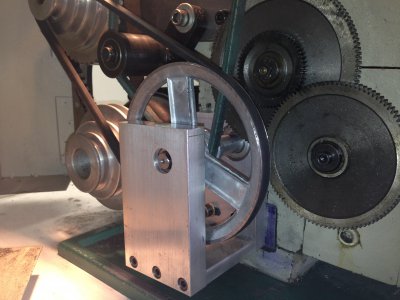

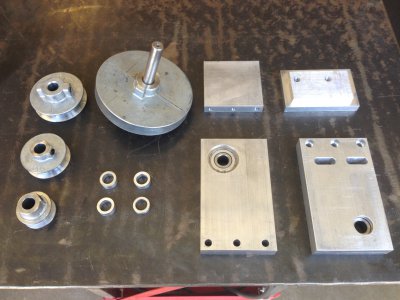

My total cost for the parts and materials was about $100. I used some scrap ¾” 6061 bar stock for the cradle. I bought a couple of surplus bearings, made the ½” shaft from a remnant and I purchased the retaining rings, pulleys and belts from McMaster-Carr. I figured out the correct dimensions to provide the desired ratios, the right position to mount it and a means to bolt it down without drilling or tapping one hole in the lathe. Instead, I utilized the void in the casting and made a nut plate for mounting it. I then used some epoxy putty to permanently mount the nut plate inside the casting.

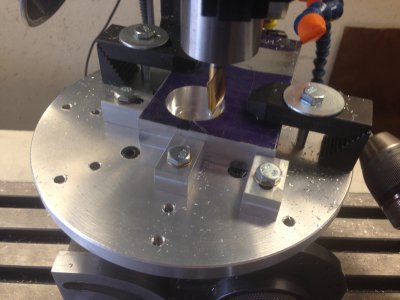

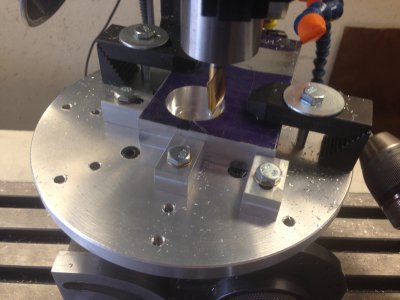

I did most of the machine work on the mill and rotary table (RT) because I wanted to test my new RT tooling plate and work stops I recently made. The bearing bores could be done just as well, and probably quicker and easier in a 4-jaw chuck on the lathe.

I understand that most owners won’t feel the need to bother with this mod, but I’m sure that it will come in handy in the future and I’ll be happy to have the options available when the time comes.

Rick

Grizzly G0602 Lathe

LMS High-Torque Mini Mill

(my mill mods) http://www.hobby-machinist.com/threads/my-lms-mini-mill.22202/

I was looking inside the cover of my lathe one day while making a speed change using my “Quick Belt Change” mod that I introduced to G0602 owners a few years ago (http://www.projectsinmetal.com/forum/general-discussion/diary-of-a-new-g0602). I found that there is still a bit of space where I could build and mount a custom, triple reduction jackshaft. I began measuring and calculating and found that with different combinations of pulleys another dozen speeds are entirely possible, but that’s not necessary.

I verified my spindle speed calculations with my digital tachometer and also found that the standard speeds from Grizzly are not accurate, I got 180, 320, 507, 795, 1284 and 2466. I then optimized the various pulley combinations using commonly available parts to fill the gap below Grizzly’s 150 RPM and I settled on the 3 most practical low-end speeds of 75, 105, 147 rpm.

To use the 3rd reduction, you have to install the proper belt/pulley combination when you need it. It’s not difficult and takes only a couple of minute when used in combination with the “quick belt change” mod. I plan to only use it on rare occasions and take it off when not in use. I also developed this pulley/shaft spacer/belt/speed combination “cheat sheet” for quick reference to keep on the inside of the belt cover so I don’t have to remember what-goes-where when I need it.

I also modified a 5.5” pulley and was able to get 3 more lower speeds of 37, 60 and 80 rpm.

My total cost for the parts and materials was about $100. I used some scrap ¾” 6061 bar stock for the cradle. I bought a couple of surplus bearings, made the ½” shaft from a remnant and I purchased the retaining rings, pulleys and belts from McMaster-Carr. I figured out the correct dimensions to provide the desired ratios, the right position to mount it and a means to bolt it down without drilling or tapping one hole in the lathe. Instead, I utilized the void in the casting and made a nut plate for mounting it. I then used some epoxy putty to permanently mount the nut plate inside the casting.

I did most of the machine work on the mill and rotary table (RT) because I wanted to test my new RT tooling plate and work stops I recently made. The bearing bores could be done just as well, and probably quicker and easier in a 4-jaw chuck on the lathe.

I understand that most owners won’t feel the need to bother with this mod, but I’m sure that it will come in handy in the future and I’ll be happy to have the options available when the time comes.

Rick

Grizzly G0602 Lathe

LMS High-Torque Mini Mill

(my mill mods) http://www.hobby-machinist.com/threads/my-lms-mini-mill.22202/