- Joined

- Jun 11, 2013

- Messages

- 731

Search for 3d printer groups in your area, they seem to be all over the place. I bet they could make you a new gear faster than trying to find one in another toy to replace it, or make one yourself.

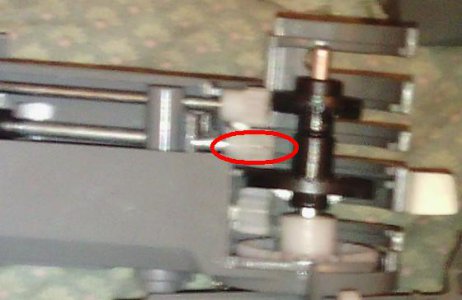

Found another problem. There's a cracked gear. If you look closely, you can see the crack in the 12 o'clock position. I turned a collar in an attempt to keep the gear from slipping on the shaft. It still slips. The aluminum collar did tighten it up a lot though. I still have to clean up the collar a bit too.

Anyone know what type of plastic these gears are made of? I'm thinking of trying bonding the gear to the shaft.

View attachment 63452

Thanks for looking!