-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Goofs & Blunders You Should Avoid.

- Thread starter David S

- Start date

- Joined

- Dec 27, 2014

- Messages

- 4,054

When its -40* don't lock your keys into your vehicle, always have a spare key in your wallet...in case you do.

IMO this also applies when it is pushing 100 outside, concerning ones work truck or van...

- Joined

- Jan 22, 2011

- Messages

- 8,031

I was on a job a couple of summers ago building a new hospital. Walked back out to the vehicle. Didn't need a key. Right rear passenger window was in tiny little pieces (safety glass). Never really figured it out. They were doing some mowing around the area, but it was record hot that day, and my vehicle is black. I looked inside thoroughly for a foreign object from the mowers.....kind of hoping it was them so I could make someone pay for the glass, but never found anything. Guess it could have bounced off. Watch where you park if there is a contract mowing crew around!

Funny thing was, even the dealer was not able to get the correct tint. It has (now has one) really dark passenger glass. Factory says no, it doesn't. I had to put the wrong glass in. I started looking, and about 80% of the ones I see on the road HAVE the near black glass. Others have a sort of goldish tint. I went aftermarket and got as dark as I could.......still burns me. I drove around with a Plexiglass window for 2 months looking and trying to get the right one. Now I see them on ebay all the time. I just hate to buy one twice. If I do, I'll try to sell this wrong one to somebody.

Funny thing was, even the dealer was not able to get the correct tint. It has (now has one) really dark passenger glass. Factory says no, it doesn't. I had to put the wrong glass in. I started looking, and about 80% of the ones I see on the road HAVE the near black glass. Others have a sort of goldish tint. I went aftermarket and got as dark as I could.......still burns me. I drove around with a Plexiglass window for 2 months looking and trying to get the right one. Now I see them on ebay all the time. I just hate to buy one twice. If I do, I'll try to sell this wrong one to somebody.

- Joined

- Apr 21, 2013

- Messages

- 208

Another tablesaw story. Back in 1987, I was ripping a 20" long board on the tablesaw and the board started to pinch the blade and was hopping a bit. I reached past the blade to hold the end down that had already been cut. At that moment, the wood caught the blade and shot out backwards, and pulled my hand with it. Completely split my thumb long ways and mangled my index finger. They ended up saving my thumb, but there isn't a joint in it, and I lost half of my index finder. It's been 29 years and I can still hear the sound of that board catching on the blade. I'm a cabinetmaker and still work with a tablesaw every day. I had respect for it before my accident, but I have a lot more now.

Jack

Fort Loramie, Ohio

Jack

Fort Loramie, Ohio

- Joined

- Feb 1, 2015

- Messages

- 9,561

I had the exact same experience. I never found any missile either. Fortunately, my comprehensive covered most of the bill.I was on a job a couple of summers ago building a new hospital. Walked back out to the vehicle. Didn't need a key. Right rear passenger window was in tiny little pieces (safety glass). Never really figured it out. They were doing some mowing around the area, but it was record hot that day, and my vehicle is black. I looked inside thoroughly for a foreign object from the mowers.....kind of hoping it was them so I could make someone pay for the glass, but never found anything. Guess it could have bounced off. Watch where you park if there is a contract mowing crew around!

The guy that came out to replace the glass told me that the tempered glass windows were extremely susceptible to scratches, as he was gingerly scraping off the sticker on the new glass. A tiny scratch could make the the window spontaneously shatter. He told me that there were a lot of replacements in hot weather due to the glass heating and the stress building to the point of shattering. The glass is designed to break into tiny pieces with square edges to help prevent injuries.

When I was in high school, I used to make an oddity called a Prince Rupert's Drop. It is made by heating glass to the melting point and allowing a drop to fall into into cold water, resulting in a teardrop shaped piece. Because the resultant stresses from the sudden cooling and shrinking were so well balanced, you could hit the drop with a hammer withou breaking it but if you snapped the thin tail of the drop off, it would shatter into dust.

- Joined

- Sep 29, 2014

- Messages

- 2,102

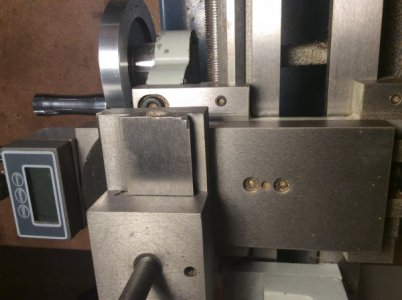

Was turning a plug for holding the bearing bores in the end of tubular parts for OD turning yesterday, didn't tighten the chuck enough and pulled one out which rotated the tool post, this in itself is not a big problem. However it is an old CNC chucker lathe with a 24 tool library, when you realign the tool post you have to reset the work shift and reset all of the other 23 tool offsets, this is time consuming and tedious at best.

- Joined

- Feb 1, 2015

- Messages

- 9,561

When I got my new G602 lathe, I hadn't built the stand for it yet. It was still strapped to the pallet on my shop floor. Being the curious person that I am, I started playing around with it. I pulled the three jaw chuck off the lathe to try the four jaw and faceplate and then reinstalled the three jaw. However, I didn't install the chuck retainers.

I powered the lathe up an started it running forward. Then I started in reverse. The chuck spun off in an instant, falling on the ways and leaving an imprint of the chuck jaw on the rear Vee way. Fortunately, that surface is used by the tailstock which never reaches that position but it serves as a reminder every time I use the lathe to make sure the chuck retainers are installed.

I powered the lathe up an started it running forward. Then I started in reverse. The chuck spun off in an instant, falling on the ways and leaving an imprint of the chuck jaw on the rear Vee way. Fortunately, that surface is used by the tailstock which never reaches that position but it serves as a reminder every time I use the lathe to make sure the chuck retainers are installed.