- Joined

- Jun 7, 2016

- Messages

- 361

Hi Fellow Machinists

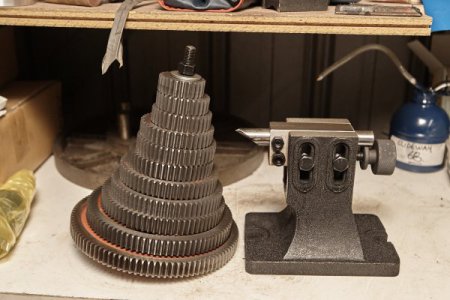

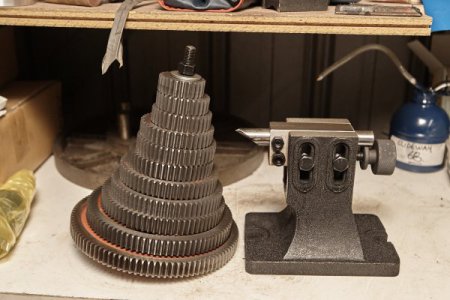

Yesterday I bought a dividing head. It is a unit that comes with change gears so it can cut helical gears as well as straight cut gears. Yes I am in way over my head, but hey why not.

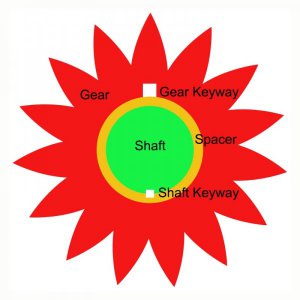

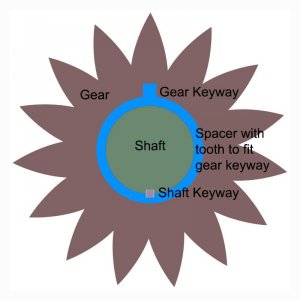

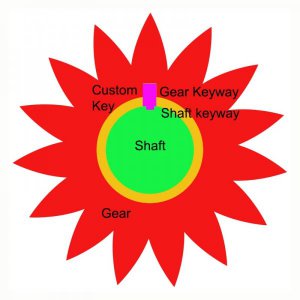

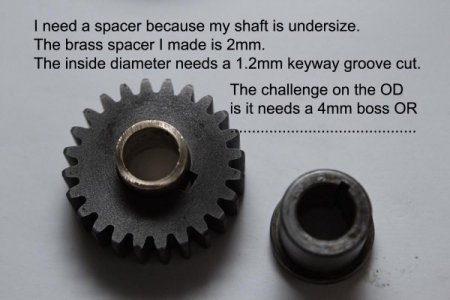

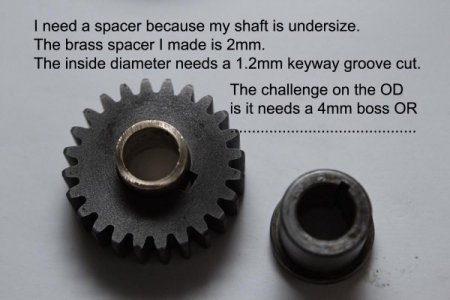

The problem I have is the change gears that should fit onto the end of the cross slide have a larger ID than the size of my shaft - see pic.

So as a way of thinking about the problem, I machined up a spacer/bush so the gear/s sit neatly on the shaft BUT it is a driven gear so it needs a way of transferring the drive (usually a keyway) - any really smart ideas????

Mal

Yesterday I bought a dividing head. It is a unit that comes with change gears so it can cut helical gears as well as straight cut gears. Yes I am in way over my head, but hey why not.

The problem I have is the change gears that should fit onto the end of the cross slide have a larger ID than the size of my shaft - see pic.

So as a way of thinking about the problem, I machined up a spacer/bush so the gear/s sit neatly on the shaft BUT it is a driven gear so it needs a way of transferring the drive (usually a keyway) - any really smart ideas????

Mal