-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

General Discussions of Atlas Lathes

- Thread starter great white

- Start date

- Joined

- Feb 7, 2013

- Messages

- 792

I have had an Atlas a long time and yes I have made modifications to cure some of the down falls but I would challenge anyone to machine something more accurate with the same size lathe. I grew up on a south bend and believe me they have plenty of down falls as well some atlas parts would appear beefy in comparison. A poor operator blames an atlas lathe.. Ray

- Joined

- Nov 10, 2013

- Messages

- 837

Beautiful restoration Holescreek, I'm sure your Grand Dad would be proud of the job you did! Can't quite make out for sure but it looks like you scraped the ways too?

I did mine in black as well, used hammered alkaline and it's held up pretty well, what did you use? Again, kudos...

- Joined

- Jan 25, 2015

- Messages

- 2,558

So it sounds like the plan is solid stand/bench first, then a QCTP second.

Would perhaps a linked belt be a worthwhile improvement after those two things are sorted?

My lathe will have to be "moveable", I've already got a design in my mind for a beam type table with a hydraulic lifting mechanism for casters. Basically, a relatively affordable 10/20 ton bottle jack and a retractable caster frame. The stand will rest on the concrete on it's solid legs once the casters are retracted.

It won't be moved much, but in a 1 car garage that shares space with my woodworking tools and a 1962 thunderbird when I need to move it for space it has to move....

Would perhaps a linked belt be a worthwhile improvement after those two things are sorted?

My lathe will have to be "moveable", I've already got a design in my mind for a beam type table with a hydraulic lifting mechanism for casters. Basically, a relatively affordable 10/20 ton bottle jack and a retractable caster frame. The stand will rest on the concrete on it's solid legs once the casters are retracted.

It won't be moved much, but in a 1 car garage that shares space with my woodworking tools and a 1962 thunderbird when I need to move it for space it has to move....

- Joined

- Jan 28, 2011

- Messages

- 3,480

The table/stand needs to be stiff, and the beam was a thought I had as well but never got there.

Definitely get an AXA tool post. It was the best $100 (at that time) upgrade that I made. Instant gratification! Be sure to get a few more holders. I bought another 5 of the Type A and should of gotten ten more. I find that I need to swap tools in the holder too many times. Also look at a tangential tool holder.

A link belt will help reduce vibrations from the drivetrain reaching the spindle. It is not a total cure, but does wonders. I get much smoother cuts on the table saw. As the belts on my equipment require replacement, I swap them to link belts. At work I am swapping the belts in our machines there as well. Reduces down time not having to disassemble a multi thousand dollar machine for a $10 belt.

Pierre

Definitely get an AXA tool post. It was the best $100 (at that time) upgrade that I made. Instant gratification! Be sure to get a few more holders. I bought another 5 of the Type A and should of gotten ten more. I find that I need to swap tools in the holder too many times. Also look at a tangential tool holder.

A link belt will help reduce vibrations from the drivetrain reaching the spindle. It is not a total cure, but does wonders. I get much smoother cuts on the table saw. As the belts on my equipment require replacement, I swap them to link belts. At work I am swapping the belts in our machines there as well. Reduces down time not having to disassemble a multi thousand dollar machine for a $10 belt.

Pierre

- Joined

- Nov 10, 2013

- Messages

- 837

Beautiful restoration Holescreek, I'm sure your Grand Dad would be proud of the job you did! Can't quite make out for sure but it looks like you scraped the ways too?

I did mine in black as well, used hammered alkaline and it's held up pretty well, what did you use? Again, kudos...

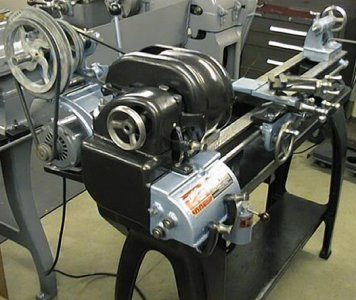

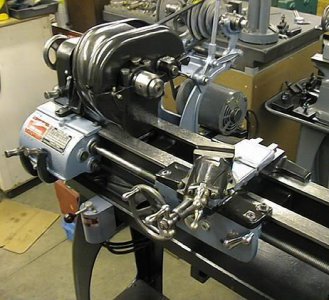

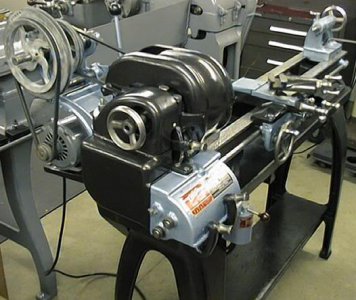

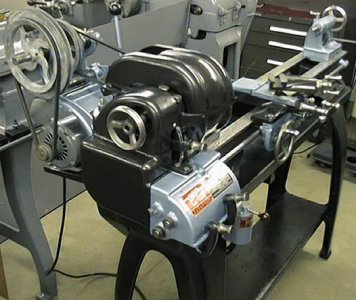

The lathe was used by my grandfather for about 30 years then by my uncle for another 30 after that. The bed ways were worn .025" for the first 18" from the head. The cross-slide was worn about .012" and even the compound had a few thousandths wear. I hand scraped the bed, surface ground and scraped the rest and painted with Rustoleum Hammered metal finish.

I intended to pass it along to a family member but sadly, I'm the last of the machinists and no one in the family is interested.

The lathe was used by my grandfather for about 30 years then by my uncle for another 30 after that. The bed ways were worn .025" for the first 18" from the head. The cross-slide was worn about .012" and even the compound had a few thousandths wear. I hand scraped the bed, surface ground and scraped the rest and painted with Rustoleum Hammered metal finish.

I intended to pass it along to a family member but sadly, I'm the last of the machinists and no one in the family is interested.

I've never scraped anything myself so only have admiration for those that do/can...

Gosh, hope someone in the family will develop at least a curiosity about machining or gets interested... funny thing life is sometimes huh?

So it sounds like the plan is solid stand/bench first, then a QCTP second.

Would perhaps a linked belt be a worthwhile improvement after those two things are sorted?

My lathe will have to be "moveable", I've already got a design in my mind for a beam type table with a hydraulic lifting mechanism for casters. Basically, a relatively affordable 10/20 ton bottle jack and a retractable caster frame. The stand will rest on the concrete on it's solid legs once the casters are retracted.

It won't be moved much, but in a 1 car garage that shares space with my woodworking tools and a 1962 thunderbird when I need to move it for space it has to move....

How are you setup for tools? Hand tools mostly or power? Reason I ask, torsion boxes work terrifically for making a very strong, stable base. It's what I did, and would do it again even if it was a fair amount of work...

I'll see if I can find or take some pics if you want of the bench and the motor belt tensioning thingamabob I made. When I first got the lathe, that was my #1 first goal: removing/deadening vibrations.