- Joined

- Nov 14, 2014

- Messages

- 851

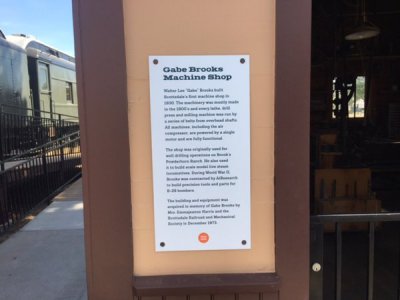

Stopped by the McCormick-Stillman Railroad Park in Scottsdale this week to ride their 15" gauge miniature train and 'discovered' this fantastic 12' x 12' square machine shop preserved in their small RR museum. Seems to me this is the most perfectly designed one man shop I've ever seen. And yes, it is 144 sq feet - on the outside of the building. I stepped off the dimensions - 4 long paces each side. (Correction - actually the shop is 3 x 4 paces, so 10' x12' or just under 120 sq feet interior dimension! A masterpiece of organization)

'Gabe' Brooks was an early day 'rancher' around the Scottsdale area, settling just east of Phoenix in 1917. He put this shop together around 1930. He was a prolific live steamer and also used the equipment to support his water well drilling business. Following his passing in the late 1980's a benefactor eventually preserved his shop building and equipment and had it moved and donated to the McCormic RR park in Scottsdale - where it is displayed today. Apparently the Scottsdale Live Steamers assisted in maintaining the shop for many years. Today the City of Scottsdale owns and operates the park, museum, on site carousel, and

Stillman Ranch's 15" ga railroad.

BTW, most all the equipment runs off a functioning overhead belt drive system. A huge 18" diameter electric motor is mounted up in the rafters to the right of the pictures and powers the overhead drive system.

The electric lamps are hung with weights on pulleys mounted in the rafters. Need more light on your work? Just reach up and pull the light shade down. The shade is hung from a pulley and A little 2 or 3 pound weight on the other end of the pulley slides up and down and holds the lampshade wherever you place it.

The little 12" power hacksaw and shop made 1" diameter vertical cutter have their own small motor driven electric motors? Durn modernization. What's the world coming to with this miserable new junk coming on the market...

Photos are from left to right, around the shop, looking in from the door.

The lathe is a South Bend 11" or 12" -couldn't quite read the tag on the end. The drill press is a 10" camelback, with spare drills placed on holders in the back.

Man, this has everything, even a drafting table and 8' workbench- and plenty of room to walk around. I gotta down size when I get home!

Glenn

'Gabe' Brooks was an early day 'rancher' around the Scottsdale area, settling just east of Phoenix in 1917. He put this shop together around 1930. He was a prolific live steamer and also used the equipment to support his water well drilling business. Following his passing in the late 1980's a benefactor eventually preserved his shop building and equipment and had it moved and donated to the McCormic RR park in Scottsdale - where it is displayed today. Apparently the Scottsdale Live Steamers assisted in maintaining the shop for many years. Today the City of Scottsdale owns and operates the park, museum, on site carousel, and

Stillman Ranch's 15" ga railroad.

BTW, most all the equipment runs off a functioning overhead belt drive system. A huge 18" diameter electric motor is mounted up in the rafters to the right of the pictures and powers the overhead drive system.

The electric lamps are hung with weights on pulleys mounted in the rafters. Need more light on your work? Just reach up and pull the light shade down. The shade is hung from a pulley and A little 2 or 3 pound weight on the other end of the pulley slides up and down and holds the lampshade wherever you place it.

The little 12" power hacksaw and shop made 1" diameter vertical cutter have their own small motor driven electric motors? Durn modernization. What's the world coming to with this miserable new junk coming on the market...

Photos are from left to right, around the shop, looking in from the door.

The lathe is a South Bend 11" or 12" -couldn't quite read the tag on the end. The drill press is a 10" camelback, with spare drills placed on holders in the back.

Man, this has everything, even a drafting table and 8' workbench- and plenty of room to walk around. I gotta down size when I get home!

Glenn

Last edited: