Hello....

So i think I'm going to change the motor on my mill to a 3 phase with a VFD.

I have a GS3 on my lathe with a leason motor and its been great. I do change gears occasionally with the lathe when needed.

I really like how the G078 has it so there is no belt changes. wondering if they use an inverter duty motor???

Looking for suggestions on Motors... right now mine has a 1 hp single phase motor on it.

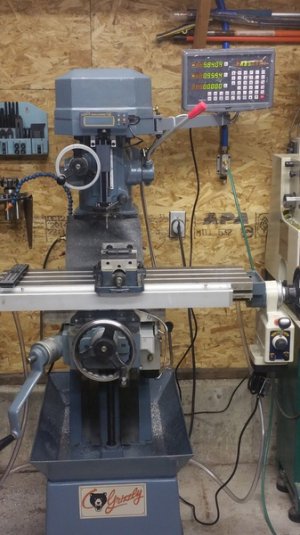

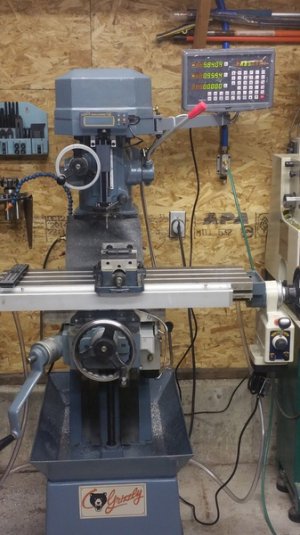

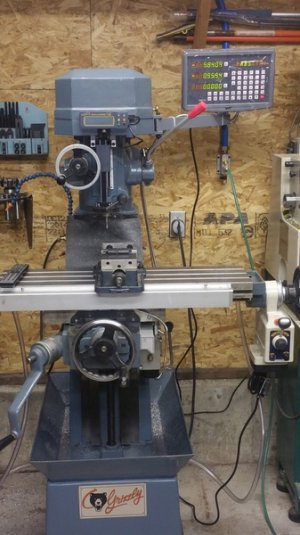

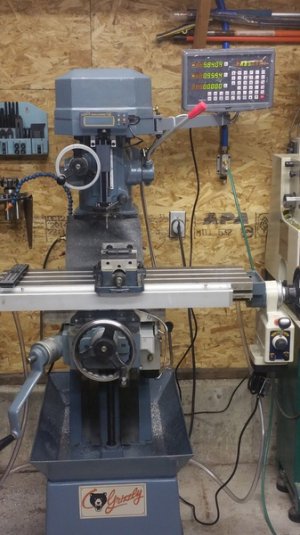

Heres a pic of the mill....

So i think I'm going to change the motor on my mill to a 3 phase with a VFD.

I have a GS3 on my lathe with a leason motor and its been great. I do change gears occasionally with the lathe when needed.

I really like how the G078 has it so there is no belt changes. wondering if they use an inverter duty motor???

Looking for suggestions on Motors... right now mine has a 1 hp single phase motor on it.

Heres a pic of the mill....

Last edited: