- Joined

- Dec 18, 2019

- Messages

- 6,447

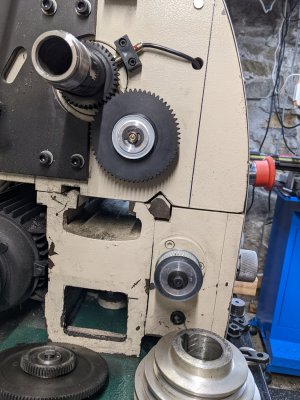

I need to pull the gear shaft #706 and remove the 27T gear and the 60T plastic gear. Do I have to remove the spindle pulley assembly to do this? If so, what is the procedure for re-torquing the spanner nut 37mm ref #24? The lathe parts list says there are tapered roller bearings.

The keyed bushing is damaged and needs to be replaced. I also need to do some machining of the parts to enable me to install a timing pulley in place of the 27T cast iron gear for my own ELS. I have removed the E-clip. The 27T gear does not want to come off. The 60T gear seems to hit the pulley C and stops.

Thanks for any and all insight on this.

The keyed bushing is damaged and needs to be replaced. I also need to do some machining of the parts to enable me to install a timing pulley in place of the 27T cast iron gear for my own ELS. I have removed the E-clip. The 27T gear does not want to come off. The 60T gear seems to hit the pulley C and stops.

Thanks for any and all insight on this.