- Joined

- Mar 26, 2014

- Messages

- 211

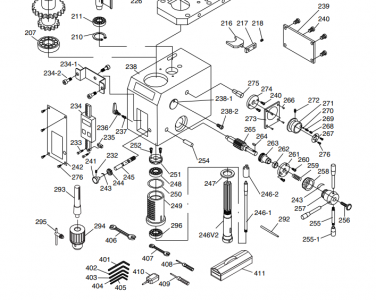

Good morning. I have a g0704 mill, used less than an hour. When I put in an r8 collet I never feel it connect with a locating pin. I’ve looked down the column and don’t see one. I can’t fell one when I rotate the column. I’ve looked at the parts list and don’t see one. Am I missing something? Any help would be appreciated,

Thanks

Thanks