- Joined

- Dec 30, 2014

- Messages

- 259

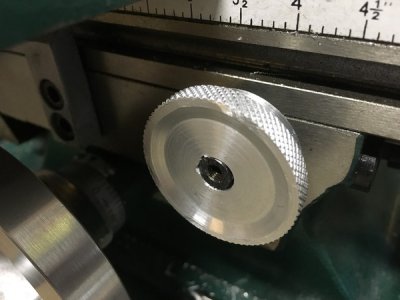

I made this counterweight a while ago and sent a few pictures of it to a local friend recently and thought I would post them here for anyone thinking about something similar.

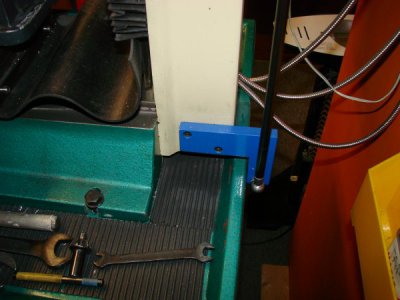

According to my friend who converted his 759 to CNC the head weighs in at about 65lbs, so my counterweight is an old dewalt tool box with 65lbs of lead shot. I reworked the cheap pulleys and added two each roller skate bearings. The original pulleys were dragging a bit on the rope and I could see the grey discoloration indicating the rope was sliding instead of the pulley turning. It really reduces the up cranking force required and if I decide to put a motor on the Z axis someday the counterweight will really help there as well.

Jim

According to my friend who converted his 759 to CNC the head weighs in at about 65lbs, so my counterweight is an old dewalt tool box with 65lbs of lead shot. I reworked the cheap pulleys and added two each roller skate bearings. The original pulleys were dragging a bit on the rope and I could see the grey discoloration indicating the rope was sliding instead of the pulley turning. It really reduces the up cranking force required and if I decide to put a motor on the Z axis someday the counterweight will really help there as well.

Jim