Hello everyone,

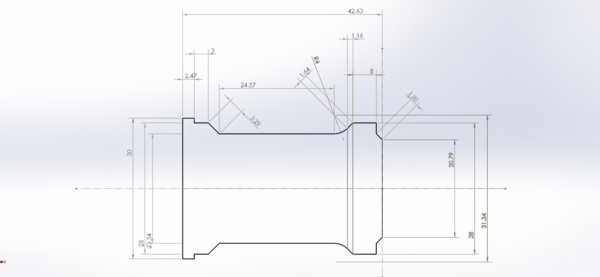

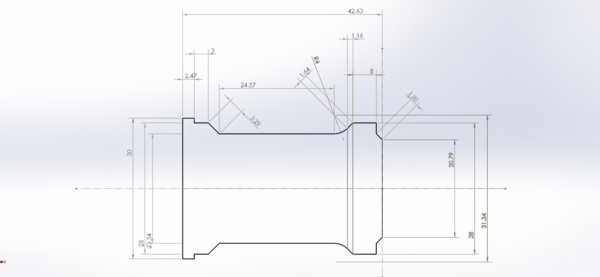

I am doing a project at my uni which is making a chess piece using CNC machine. I need to design the shape of the chess and write a g-code for it. This g-code will be used for turning and milling machine with X Z axis. I have done my design, it looks simple but I am stuck at writing g-code. I need some help. Could anybody please help me to write a g-code for it? Thank you very much.

I am doing a project at my uni which is making a chess piece using CNC machine. I need to design the shape of the chess and write a g-code for it. This g-code will be used for turning and milling machine with X Z axis. I have done my design, it looks simple but I am stuck at writing g-code. I need some help. Could anybody please help me to write a g-code for it? Thank you very much.