-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

B

BRIAN

Forum Guest

Register Today

A shrink fit experiment, trying to determine the best way to shrink fit the bronze valve cages and the allowance necessary.

Two samples one of bronze (Quality unknown) and the other of 6082 aluminium both 5/8" dia.

The ambient temp 19°c. both pieces measured and true size recorded.

The bronze was placed in the freezer for 24 hrs at -19 °c on removal no change in size was recorded.

The 6082 was placed on a electric hot plate for 15 min's on re measuring it had increased in diameter .005"

It seems to me that .003"interferance may provide a tight fit and ease of fitting .

Brian.

Two samples one of bronze (Quality unknown) and the other of 6082 aluminium both 5/8" dia.

The ambient temp 19°c. both pieces measured and true size recorded.

The bronze was placed in the freezer for 24 hrs at -19 °c on removal no change in size was recorded.

The 6082 was placed on a electric hot plate for 15 min's on re measuring it had increased in diameter .005"

It seems to me that .003"interferance may provide a tight fit and ease of fitting .

Brian.

B

BRIAN

Forum Guest

Register Today

B

BRIAN

Forum Guest

Register Today

The bronze is due this week, also I found that I have the need for a internal mic." Well I do don't I" so that is due in the post tomorrow.

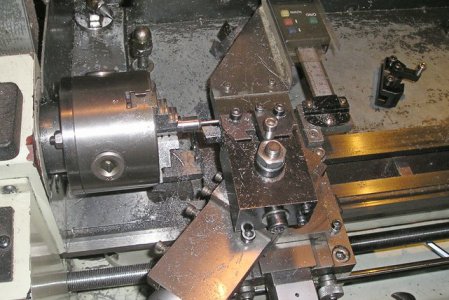

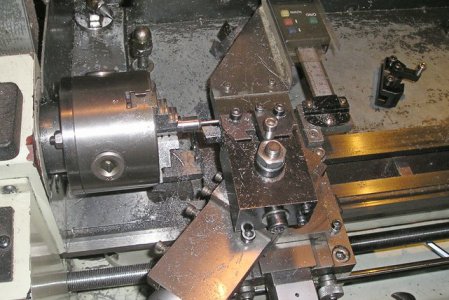

While I am waiting I have made a seating cutter for the valves, from drill rod , turning the stem down from 1/2 " to 3mm was a bit buttock clenching

but we got er done as they say.

Slowly slowly Brian.

While I am waiting I have made a seating cutter for the valves, from drill rod , turning the stem down from 1/2 " to 3mm was a bit buttock clenching

but we got er done as they say.

Slowly slowly Brian.

B

BRIAN

Forum Guest

Register Today

The bronze is in the depot I will have it in my grimy little hands tomorrow

Brian..

Brian..

- Joined

- Oct 21, 2014

- Messages

- 2,156

seat cutter looks nice. IT almost looks like you could have drilled it and pressed or interference fit a small shaft into the cutter if you had to. In fact it reminds me of one that I use to use but it was designed where you put a rod in the valve guide, then it spun on that to cut the seat then you removed it then put on the second one for a dual angle cut on the seat. but that was over 35 years ago that I did that.

B

BRIAN

Forum Guest

Register Today

I know the very thing you are talking about Ken my son probably still has mine including a throat cutter probably last used on the rebuild of his Healy

100/6 .

The material for the Cages/Cam boxes/Cams and valves are now in my possession so it's time to move on.

The first valve cage is ready to fit, final machining to be done after fitting in case there is any distortion.

I will make the other tomorrow each is matched to the head :003" interference.

Brian.

100/6 .

The material for the Cages/Cam boxes/Cams and valves are now in my possession so it's time to move on.

The first valve cage is ready to fit, final machining to be done after fitting in case there is any distortion.

I will make the other tomorrow each is matched to the head :003" interference.

Brian.