- Joined

- Jul 17, 2013

- Messages

- 99

I think I might do that. I've almost talked myself out of the G0602 and into a G4003G.......

Sent from my iPad using Tapatalk

Sent from my iPad using Tapatalk

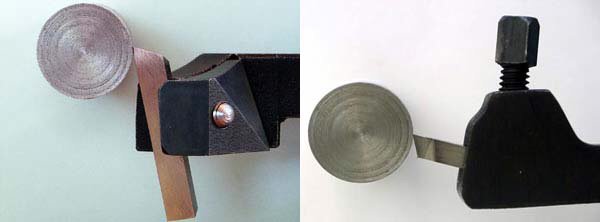

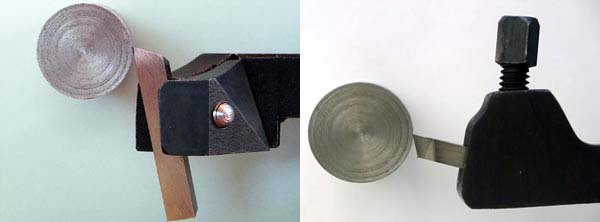

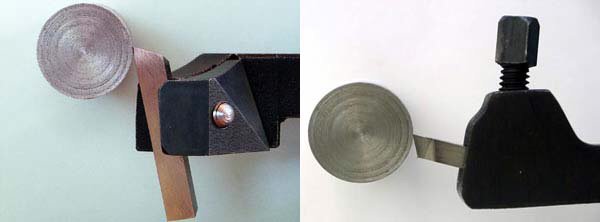

Not to be a smart ass but exactly how is this different? The top rake appears to be the same yet I suspect that holding the tool in such a way would drive the tool right out of the clamp on holder. If one were going to grind a HSS tool anyway then why not just use the same geometry without buying a dodgy looking tool holder.

I'd hold off buying any tooling, tool holders, or QCTP for the lathe until you make up your mind on which lathe. As for chucks the G4003G has an oddball size D1-5 spindle. There's a crap load of lathes from smaller than the G4003G up through much larger heavier 14x40 lathes that use a D1-4 spindle. The 16x40's are typically D1-6. Relatively few lathes use the D1-5. Having owned a G4003G for a couple of years if I had it to do over I'd buy a larger lathe and nothing from CHINA. Make no mistake the G4003G is a CHINA lathe with the typical CHINA quality issues. Hey you get what you pay for and its not fair comparing it to a lathe costing twice or three times the price just know that you are buying CHINA.