- Joined

- Nov 10, 2013

- Messages

- 376

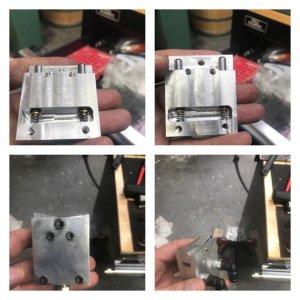

Soooooo...... I'm a newer member to the forum. I've a lot of time on my lathe but only used my enco RF clone as a glorified drillpress. I picked up a BP clone a couple weeks back I've been crazy busy at work so I've just been buying tooling. The damn thing was 3 phase being that I converted my lathe to 3 phase and already had a drive I had to build a box allowing the drive to control both machines with just a flip of a switch. tonight I actually got some time on the new to me machine. All I've got to say is any of y'all doing any milling work without a dro my hat is off to you!!!!!!! I honestly couldn't imagine doing any milling without a dro. I won't lie I was super intimidated by the milling machine. My other machine wouldn't tram to save a life. I broke a million end mills and basically said screw this and pushed it in a corner. I figure if I'm gonna have a fancy mill with a fancy dro I may as well have a pneumatic draw bar. I watched a million YouTube videos picked and chose little things I liked from all of them. It's super nice having a machine that doesn't chatter and break things. I hope this project turns out well for me this has been a super enjoyable evening.