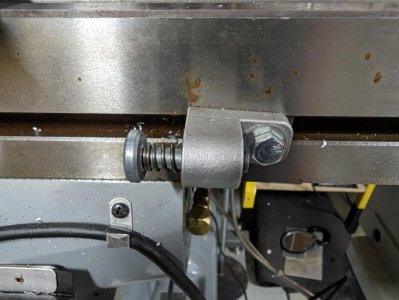

I need to fabricate some custom spring-loaded travel stop similar to the pic below. Commonly available ones don't have the proper dimensions for my application.

But am not finding something suitable to serve as the "plunger". I thought maybe some un-threaded weld studs with a round head might fill the bill, but how to hold such a thing while cutting a groove for a circlip, or an axial hole in the end for a small screw and washer?

Any ideas?

But am not finding something suitable to serve as the "plunger". I thought maybe some un-threaded weld studs with a round head might fill the bill, but how to hold such a thing while cutting a groove for a circlip, or an axial hole in the end for a small screw and washer?

Any ideas?