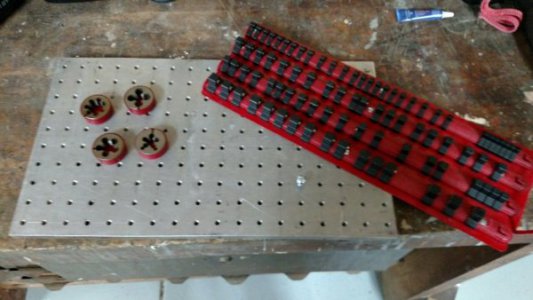

I've acquired a 10in x 18in x 1/2in thick aluminum plate that has 1/4in tapped holes on a 1in grid, as part of a small lot of items from the local used-tool store (see attached pics).

I don't know the original application, but I'm wondering if it might make a decent mini pallet, if I trim it back to about 1/2 size (10in x 9in).

I like the designs I've seen on the web where one edge of the plate is bolted to 2in diameter steel round stock, and it is clamped in the mill vise at the desired angle (see attached pic).

Even though one edge would be supported by the 2in diameter round stock clamped in my 6in Kurt, and the opposite edge is supported by machinists jacks, or similar, I'm concerned that being 1/2in thick that it may not be stout enough.

Can anyone offer opinions?

I don't know the original application, but I'm wondering if it might make a decent mini pallet, if I trim it back to about 1/2 size (10in x 9in).

I like the designs I've seen on the web where one edge of the plate is bolted to 2in diameter steel round stock, and it is clamped in the mill vise at the desired angle (see attached pic).

Even though one edge would be supported by the 2in diameter round stock clamped in my 6in Kurt, and the opposite edge is supported by machinists jacks, or similar, I'm concerned that being 1/2in thick that it may not be stout enough.

Can anyone offer opinions?

Last edited: