- Joined

- Jan 5, 2023

- Messages

- 19

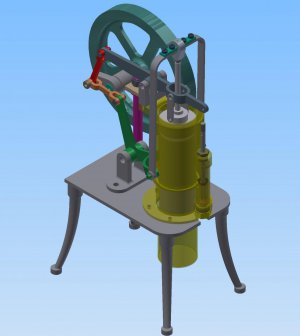

Totally hand made using raw angle iron and pipe, with brass and aluminum parts.

Built using plans from an article in Live Steam Magazine October through December 1978.

Just a short video. Please enjoy. A longer video is here

View attachment IMG_0052.MOV

Built using plans from an article in Live Steam Magazine October through December 1978.

Just a short video. Please enjoy. A longer video is here

View attachment IMG_0052.MOV