- Joined

- Nov 23, 2014

- Messages

- 2,606

I used to have a pretty large Erector set collection. I started collecting them in 2000 and at one time had over 350 restored sets! I got over the “gotta have ‘em all” mentality and started paring down around 5 years ago. Proud to say at the time of this post I’m down to under 150 sets!

There is an approximately 400 member collecting club called the A. C. Gilbert Heritage Society (www.acghs.org); great group of mainly guys interested in the science toys produced by the A. C. Gilbert Company. We had a member named Joe Long who did an amazing job reproducing parts from the 1920’s and 1930’s. Unfortunately, Joe passed away a few years ago leaving a big void in the group. I’ve been attempting to follow in Joe’s rather large footsteps by starting to reproduce some of the old parts.

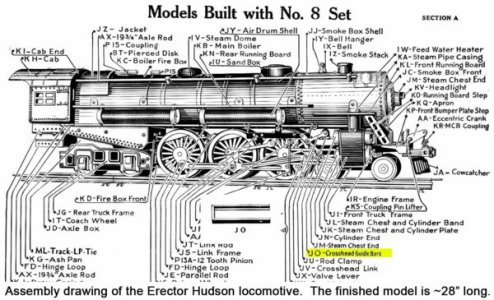

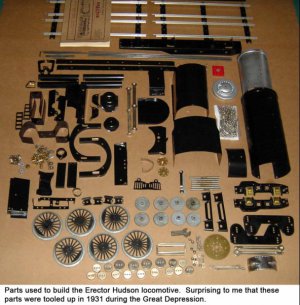

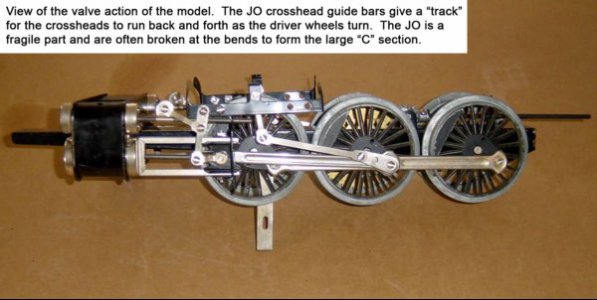

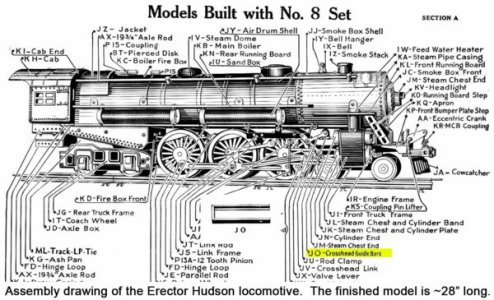

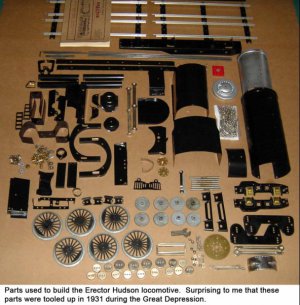

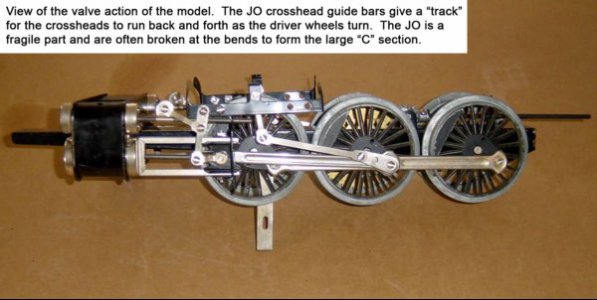

The part in particular here is Erector set part JO, crosshead guide bars, used exclusively in the 1931 – 1937 Erector Hudson Locomotive model. Pretty esoteric part to make? Well, a built up Hudson model goes for around $1000 and if you’re missing parts, your options are limited as they are no longer available at the hobby shop! The part JO is a particularly fragile part; “U” shaped section from nickel-plated 0.020” steel. The part was formed in the flat, bent to a “C” section, then notched to form a larger “U” really stressing the metal at the bends. By the way, the built up locomotive is close to 30 inches long.

I started by measuring up an original part. Then cut a piece of steel to fit into the small “U” section. Spotted and drilled 1/8” holes which would be used later with a transfer punch to mark the position of a number of holes.

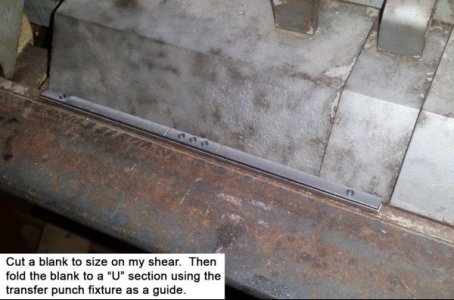

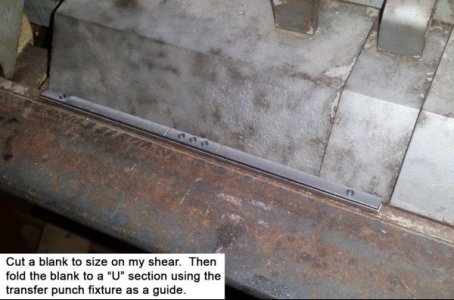

Developed a blank size by trial and error, overall length was pretty easy, but took a couple of shots to get the blank width correct. The blank is bent up on either side to form a "U" section, tool wide or too narrow of a blank and the section looks like a "J" instead of a "U".

Cut the blanks to size and folded up the “U” section on my DiAcro brake. Used the punch fixture as a positioning guide on the brake. After bending, set the punch fixture in place and transfer punched the holes. Knocked in the holes on my Roper Whitney punch press. The hole fixture also has scribed lines marking the center location of the bend notches. Those locations were transferred to the “U” section with a square and scribe.

The notches were put in with a square file on my Oliver die filer. GREAT tool for working sheet metal by the way.

Last step was to bend the “U” sections into a “C” and give them a little tap on the ends with a hammer to get the sides parallel. Original parts were made from CRS and nickel-plated. I used 304 stainless in a #4 finish for these which is really close in appearance to nickel-plating, plus makes the parts a little more durable. Coming to an Erector set show in your neighborhood!

Bruce

There is an approximately 400 member collecting club called the A. C. Gilbert Heritage Society (www.acghs.org); great group of mainly guys interested in the science toys produced by the A. C. Gilbert Company. We had a member named Joe Long who did an amazing job reproducing parts from the 1920’s and 1930’s. Unfortunately, Joe passed away a few years ago leaving a big void in the group. I’ve been attempting to follow in Joe’s rather large footsteps by starting to reproduce some of the old parts.

The part in particular here is Erector set part JO, crosshead guide bars, used exclusively in the 1931 – 1937 Erector Hudson Locomotive model. Pretty esoteric part to make? Well, a built up Hudson model goes for around $1000 and if you’re missing parts, your options are limited as they are no longer available at the hobby shop! The part JO is a particularly fragile part; “U” shaped section from nickel-plated 0.020” steel. The part was formed in the flat, bent to a “C” section, then notched to form a larger “U” really stressing the metal at the bends. By the way, the built up locomotive is close to 30 inches long.

I started by measuring up an original part. Then cut a piece of steel to fit into the small “U” section. Spotted and drilled 1/8” holes which would be used later with a transfer punch to mark the position of a number of holes.

Developed a blank size by trial and error, overall length was pretty easy, but took a couple of shots to get the blank width correct. The blank is bent up on either side to form a "U" section, tool wide or too narrow of a blank and the section looks like a "J" instead of a "U".

Cut the blanks to size and folded up the “U” section on my DiAcro brake. Used the punch fixture as a positioning guide on the brake. After bending, set the punch fixture in place and transfer punched the holes. Knocked in the holes on my Roper Whitney punch press. The hole fixture also has scribed lines marking the center location of the bend notches. Those locations were transferred to the “U” section with a square and scribe.

The notches were put in with a square file on my Oliver die filer. GREAT tool for working sheet metal by the way.

Last step was to bend the “U” sections into a “C” and give them a little tap on the ends with a hammer to get the sides parallel. Original parts were made from CRS and nickel-plated. I used 304 stainless in a #4 finish for these which is really close in appearance to nickel-plating, plus makes the parts a little more durable. Coming to an Erector set show in your neighborhood!

Bruce