- Joined

- Dec 26, 2015

- Messages

- 2,079

Earlier this year I purchased an ER40 collet chuck with integral D1-4 mounting from hhip.com (their part #3901-5042). I wasn't completely satisfied with the quality and it didn't have sufficient stick-out from the spindle nose to get cutting tools to it using my solid tool post. I also had inconsistent registration to the spindle with unacceptable TIR. This is that chuck.

I decided to replace it with a better solution - one that was adjustable to the centerline of the spindle rotation, along the lines for an Adjust True or Set Tru scroll chuck.

After some research I bought an ER40 plain back collet chuck from an eBay seller, did some checking of it when it arrived and concluded it was built to decent tolerances. Then I bought a Bison D1-4 camlock backing plate, some 1045 stock from McMaster and set about making a sleeve to join the Bison backing plate to the ER40 collet chuck.

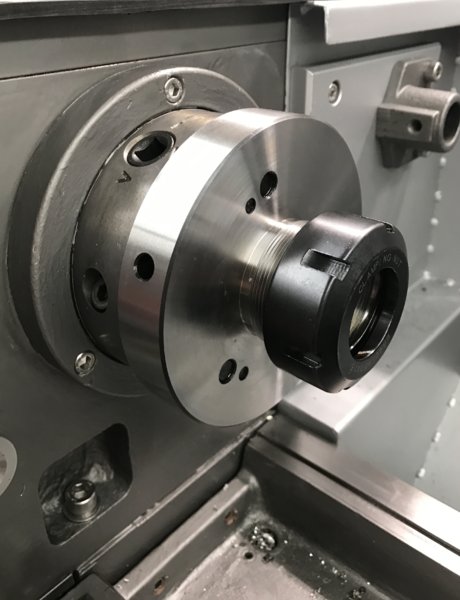

This is the result - it has four M8 set screws around the perimeter that can be used to precisely center the chuck. I'm very happy with the result.

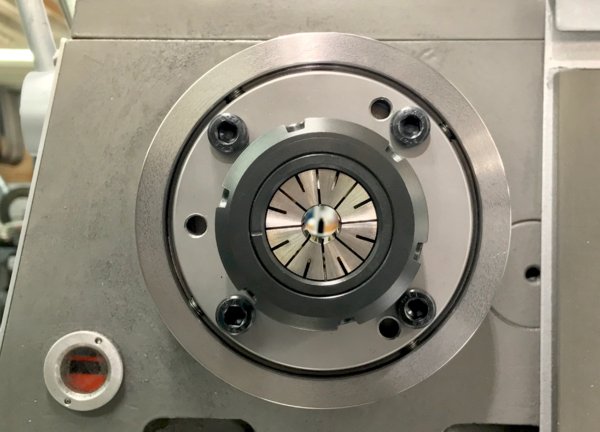

Here's a nose-on view - you can see the centering adjustment set screws if you look closely.

Although a bit expensive, the Bison D1-4 backing plate is exactly what I expected - outstanding quality:

I'm attaching the drawing for this implementation in case anyone wants to do the same.

Also, there are more images and description of the build process here:

https://flic.kr/s/aHsm1PtHsq

Hopefully this will be useful to someone here. Enjoy.

I decided to replace it with a better solution - one that was adjustable to the centerline of the spindle rotation, along the lines for an Adjust True or Set Tru scroll chuck.

After some research I bought an ER40 plain back collet chuck from an eBay seller, did some checking of it when it arrived and concluded it was built to decent tolerances. Then I bought a Bison D1-4 camlock backing plate, some 1045 stock from McMaster and set about making a sleeve to join the Bison backing plate to the ER40 collet chuck.

This is the result - it has four M8 set screws around the perimeter that can be used to precisely center the chuck. I'm very happy with the result.

Here's a nose-on view - you can see the centering adjustment set screws if you look closely.

Although a bit expensive, the Bison D1-4 backing plate is exactly what I expected - outstanding quality:

I'm attaching the drawing for this implementation in case anyone wants to do the same.

Also, there are more images and description of the build process here:

https://flic.kr/s/aHsm1PtHsq

Hopefully this will be useful to someone here. Enjoy.

Attachments

Last edited: