- Joined

- Feb 2, 2014

- Messages

- 1,059

A few months back I posted a end mill sharpener I had made. http://www.hobby-machinist.com/threads/end-mill-sharpener.45541/

One of the last posts was from benmychree who made some suggestions for ways to improve the sharpener. At the time I was deep into a different project and since the sharpener was working OK for me I just filed it away. The more I thought about it the more I realized just how much time I was wasting having to readjust the angles each time I raised or lowered the head. The height adjustment was stiff and hard to adjust accurately so lets rethink and start over.

I threw the angle setup plates I had made in the trash.

I removed the under table support bolts and their locking tab. (the locking screws for the rails that I had incorporated earlier were working well)

I removed the round tower and it's support.

I moved the index collar about 2" up the barrel to shorten the overhang.

I cut the holes of the main collar and the top collar into a square shape to accept a 2" square steel pipe.

I cut a 3/4" thick aluminum plate about 4" in diameter and drilled a center hole. I cut two adjusting slots in the plate and added some degree marks. (each mark is 1 degree) I took a 2 1/4" aluminum round and made it square on one end so it would be a nice press fit into the 2" square pipe. The other end I turned down so it would be a press fit into the base plate and be long enough to extend out the bottom by 1/4". I drilled a hole in the table to accept the 1/4" round end so it would act as the boss.

Here the parts are all pressed together and two hold down stops I made.

And all the pieces fitted.

In order to test my changes I took a 1/4" 4 flute extra long end mill to sharpen. It was in really bad shape and ended being only 0.225 in diameter when the flutes cleaned up. The cutting end cleaned up nicely and now I have my extra long end mill back and cutting.

My setup time was reduced 4 fold and much more accurately then before.

Thanks for looking

Ray

One of the last posts was from benmychree who made some suggestions for ways to improve the sharpener. At the time I was deep into a different project and since the sharpener was working OK for me I just filed it away. The more I thought about it the more I realized just how much time I was wasting having to readjust the angles each time I raised or lowered the head. The height adjustment was stiff and hard to adjust accurately so lets rethink and start over.

I threw the angle setup plates I had made in the trash.

I removed the under table support bolts and their locking tab. (the locking screws for the rails that I had incorporated earlier were working well)

I removed the round tower and it's support.

I moved the index collar about 2" up the barrel to shorten the overhang.

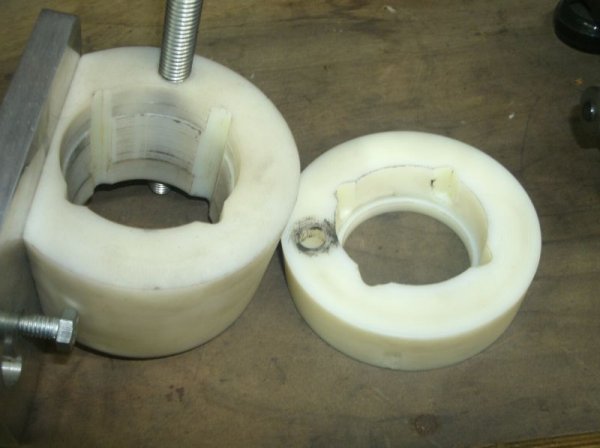

I cut the holes of the main collar and the top collar into a square shape to accept a 2" square steel pipe.

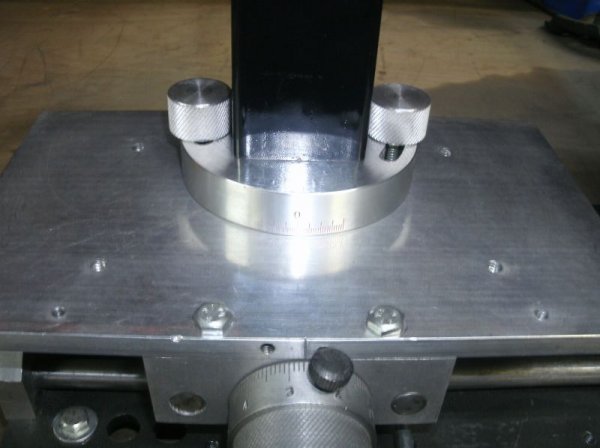

I cut a 3/4" thick aluminum plate about 4" in diameter and drilled a center hole. I cut two adjusting slots in the plate and added some degree marks. (each mark is 1 degree) I took a 2 1/4" aluminum round and made it square on one end so it would be a nice press fit into the 2" square pipe. The other end I turned down so it would be a press fit into the base plate and be long enough to extend out the bottom by 1/4". I drilled a hole in the table to accept the 1/4" round end so it would act as the boss.

Here the parts are all pressed together and two hold down stops I made.

And all the pieces fitted.

In order to test my changes I took a 1/4" 4 flute extra long end mill to sharpen. It was in really bad shape and ended being only 0.225 in diameter when the flutes cleaned up. The cutting end cleaned up nicely and now I have my extra long end mill back and cutting.

My setup time was reduced 4 fold and much more accurately then before.

Thanks for looking

Ray