A

Alan H.

Forum Guest

Register Today

I am putting this thread up to share with others my experience of installing an Easson 12B DRO on a PM1340GT lathe. I chose the Easson 12B because I have the same 3 axis model on my mill and it made sense to stick with the same manufacturer and have the same systems on both machines.

I bought the kit from Quality Machine Tools and as usual for them, it was delivered in a very timely manner and packaged well. It is a universal kit and comes with scales that fit the 1340 and does not limit its travel/capacity in any way. The kit includes the X and Y scales, readers, guards, display, power supply, mounts, brackets and mounting hardware.

Here’s what was in the box:

It is a kit and as such you have to trim and fit some of the brackets. The kit comes with fasteners but I found that I needed to buy additional cap screws, etc. to meet my needs for the installation. Easson does include instructions that are good relative to tolerances and setup but there are gaps. I also received help from the Forum via another recent thread with photos of one other install by QMT and one of an earlier version of an Easson (thanks to MonkMan, Brad S and mksj).

The X scale – I trimmed the mounting bar to fit. Used some cap screws I provided to attach it to the cross slide. I trimmed the angle bracket for the X reader to mount and attached it to the bosses on the carriage. I made sure to set the elevation of the assembly properly so that the sheet metal guard fit well and was at the right height. The guard connects to the end caps on the X-scale. I tapped the holes on the end caps for a 1/4” – 20 button head and trimmed and drilled the guard to fit. I chose to cover the cross slide lock and put a tensioner/lock on the other side as mksj and many others have done.

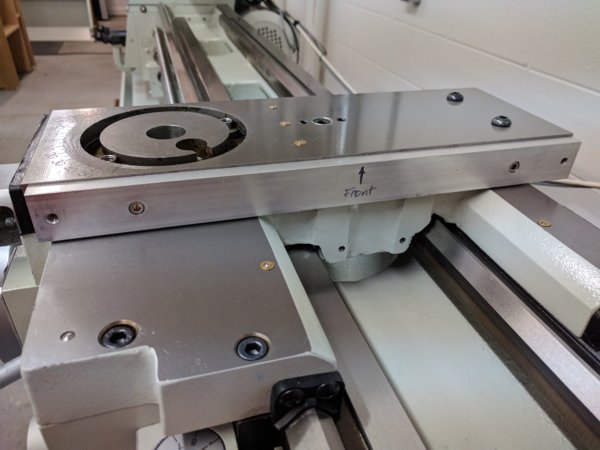

Mounting bar trimmed and mounted on cross slide:

Reader angle mount after being trimmed:

X scale installed:

Cover in place:

The Y scale – The kit comes with brackets to hang off the back of the carriage to carry the Y scale reader. I chose to make new brackets. I had some decent stock in my inventory including an anodized plate. I configured and dimensioned the brackets such that the elevation of the finished Y scale would be below the gap bed and not hanging below the bed casting opening underneath where it could get bumped cleaning chips out, etc.

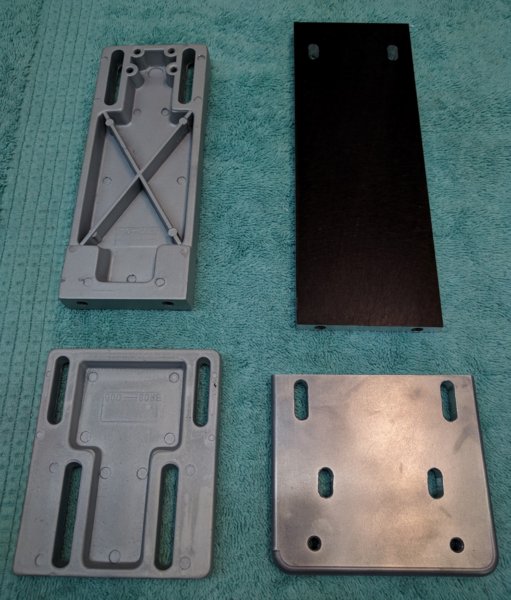

Brackets that came with the kit and the ones I made:

I mounted the Y scale to match the elevations I had chosen and then shimmed and adjusted it within specs. I was lucky in that my lathe’s bed is very consistent over its length in terms of being straight and square to the ways. I did have to shim the scale out on one end and also shim the other end to take some twist out of the end that was causing the scale to bow about 12 thousandths in the middle. I was able to get it flat and parallel to the carriage in both vertical and horizontal dimensions with shims and fender washers. Again, I used my own fasteners.

I made sure that I positioned the Y scale as far toward the tailstock end as possible while still clearing the backsplash mount. This keeps the reader from bumping the stop in the scale and causing damage.

Reader bracket assembled and Y scale complete:

View from the bottom of the Y scale reader:

Y scale finished:

I routed the cable such that they loop toward the tailstock end of the lathe and are suspended from a magnetic hook. This helps keep them out of the oil and chips on the headstock end.

Mounting Display – I used the display mount provided in the kit. I mounted it on the lathe’s control panel and put an 1/8” steel plate backer inside the panel which was threaded for the button heads I used to attach the bracket. My control panel is quite full with a Jacobs Control System and the drilling was done very, very carefully with temporary protection put in place! I mounted the arm pointed diagonally across the top of the lathe pointed at the opposite corner. This installation is quite rigid and gets the display out of the line of fire but is easily reached and visible.

The power supply was mounted on the back of the lathe adjacent to a 110v outlet I had installed previously that is controlled from my primary panel housing the primary power switch, VFD and breakers. I shortened the 110v power cable to the supply so I had less dangling wire. I hate dangling wire!

Set-up - I followed the instructions in the Easson manual and found them to be helpful and fairly clear. One thing that is not adequately described are the scale resolution parameters to use. For the X scale use 0.001 and for the Y scale use 0.005. These parameters assure that the display processes the inputs correctly and the distances displayed will be correct.

There are accuracy reports for each of the scales via QR code on the scale. You can retrieve the reports by scanning the code with a smart phone app. It is apparently possible to input corrections/adjustments into the display unit to accommodate for these minor inaccuracies from the Easson’s testing but I chose to ignore them since they were quite minor and wasn’t worth the effort to me.

All in all, a good product for the cost that appears to work quite well.

Sorry for the long post but I hope all this detail might help the next person who takes this on.

I bought the kit from Quality Machine Tools and as usual for them, it was delivered in a very timely manner and packaged well. It is a universal kit and comes with scales that fit the 1340 and does not limit its travel/capacity in any way. The kit includes the X and Y scales, readers, guards, display, power supply, mounts, brackets and mounting hardware.

Here’s what was in the box:

It is a kit and as such you have to trim and fit some of the brackets. The kit comes with fasteners but I found that I needed to buy additional cap screws, etc. to meet my needs for the installation. Easson does include instructions that are good relative to tolerances and setup but there are gaps. I also received help from the Forum via another recent thread with photos of one other install by QMT and one of an earlier version of an Easson (thanks to MonkMan, Brad S and mksj).

The X scale – I trimmed the mounting bar to fit. Used some cap screws I provided to attach it to the cross slide. I trimmed the angle bracket for the X reader to mount and attached it to the bosses on the carriage. I made sure to set the elevation of the assembly properly so that the sheet metal guard fit well and was at the right height. The guard connects to the end caps on the X-scale. I tapped the holes on the end caps for a 1/4” – 20 button head and trimmed and drilled the guard to fit. I chose to cover the cross slide lock and put a tensioner/lock on the other side as mksj and many others have done.

Mounting bar trimmed and mounted on cross slide:

Reader angle mount after being trimmed:

X scale installed:

Cover in place:

The Y scale – The kit comes with brackets to hang off the back of the carriage to carry the Y scale reader. I chose to make new brackets. I had some decent stock in my inventory including an anodized plate. I configured and dimensioned the brackets such that the elevation of the finished Y scale would be below the gap bed and not hanging below the bed casting opening underneath where it could get bumped cleaning chips out, etc.

Brackets that came with the kit and the ones I made:

I mounted the Y scale to match the elevations I had chosen and then shimmed and adjusted it within specs. I was lucky in that my lathe’s bed is very consistent over its length in terms of being straight and square to the ways. I did have to shim the scale out on one end and also shim the other end to take some twist out of the end that was causing the scale to bow about 12 thousandths in the middle. I was able to get it flat and parallel to the carriage in both vertical and horizontal dimensions with shims and fender washers. Again, I used my own fasteners.

I made sure that I positioned the Y scale as far toward the tailstock end as possible while still clearing the backsplash mount. This keeps the reader from bumping the stop in the scale and causing damage.

Reader bracket assembled and Y scale complete:

View from the bottom of the Y scale reader:

Y scale finished:

I routed the cable such that they loop toward the tailstock end of the lathe and are suspended from a magnetic hook. This helps keep them out of the oil and chips on the headstock end.

Mounting Display – I used the display mount provided in the kit. I mounted it on the lathe’s control panel and put an 1/8” steel plate backer inside the panel which was threaded for the button heads I used to attach the bracket. My control panel is quite full with a Jacobs Control System and the drilling was done very, very carefully with temporary protection put in place! I mounted the arm pointed diagonally across the top of the lathe pointed at the opposite corner. This installation is quite rigid and gets the display out of the line of fire but is easily reached and visible.

The power supply was mounted on the back of the lathe adjacent to a 110v outlet I had installed previously that is controlled from my primary panel housing the primary power switch, VFD and breakers. I shortened the 110v power cable to the supply so I had less dangling wire. I hate dangling wire!

Set-up - I followed the instructions in the Easson manual and found them to be helpful and fairly clear. One thing that is not adequately described are the scale resolution parameters to use. For the X scale use 0.001 and for the Y scale use 0.005. These parameters assure that the display processes the inputs correctly and the distances displayed will be correct.

There are accuracy reports for each of the scales via QR code on the scale. You can retrieve the reports by scanning the code with a smart phone app. It is apparently possible to input corrections/adjustments into the display unit to accommodate for these minor inaccuracies from the Easson’s testing but I chose to ignore them since they were quite minor and wasn’t worth the effort to me.

All in all, a good product for the cost that appears to work quite well.

Sorry for the long post but I hope all this detail might help the next person who takes this on.

Last edited by a moderator: