- Joined

- May 27, 2016

- Messages

- 3,469

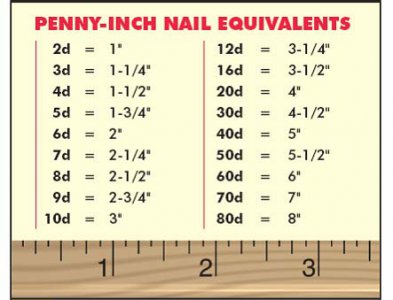

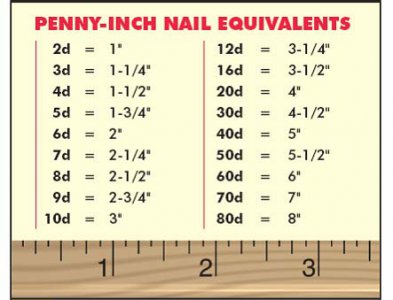

Pennies - the sizing unit increment for brad nails.

Usually, a length unit starts out referenced to some sort of length standard, but not this time! The relationship to length is arcane, and is thought to have described the number of English pennies needed to buy 100 hand forged nails. Mass manufacture has blunted the effect of inflation, but 100 six-penny nails (they are two inches long), needed 6/240ths of a pound, or half a shilling. 100 six-penny nails (2") cost sixpence. 100 eight-penny nails (2-1/2") cost eightpence. The more you paid, the longer the nail. 6d meant six denarii, but well after the Roman denarius had devalued from being made of silver.

Pounds, shillings and pence was coinage in use when I was a child. I knew that 6d would get me into a Saturday morning cinema session at the local primary school, done by pushing aside the divider wall between two classrooms, setting out chairs in rows with a centre isle, a roll-down screen, and a Bell & Howell projector at the back with valve-type speakers amplifier. Pathé and Movitone News, a Bugs Bunny cartoon, interval, then some kind of Western or crime drama. We kids were outnumbered by the grown-ups.

We have these "penny nails units", but we don't even know for sure the start point. I venture a guess that at some stage, there was a 2d coin (that's tuppence), and it was one inch in diameter, but I don't know.

It would seem that one has to first get past a cost-to-length code conversions to get an actual length dimension, then re-code into AWG or SWG to arrive at the the thickness. 18-gauge gets us to 1.02mm, or 0.403". I can see why folk just get used to whatever AWG fits their gun, and how many pennies long is good for their wood without sticking out the other side

I am still figuring out the nails. I guess it will be awhile before I get to know which nailer best suits me, and whether it shall be air, or cordless electric

Usually, a length unit starts out referenced to some sort of length standard, but not this time! The relationship to length is arcane, and is thought to have described the number of English pennies needed to buy 100 hand forged nails. Mass manufacture has blunted the effect of inflation, but 100 six-penny nails (they are two inches long), needed 6/240ths of a pound, or half a shilling. 100 six-penny nails (2") cost sixpence. 100 eight-penny nails (2-1/2") cost eightpence. The more you paid, the longer the nail. 6d meant six denarii, but well after the Roman denarius had devalued from being made of silver.

Pounds, shillings and pence was coinage in use when I was a child. I knew that 6d would get me into a Saturday morning cinema session at the local primary school, done by pushing aside the divider wall between two classrooms, setting out chairs in rows with a centre isle, a roll-down screen, and a Bell & Howell projector at the back with valve-type speakers amplifier. Pathé and Movitone News, a Bugs Bunny cartoon, interval, then some kind of Western or crime drama. We kids were outnumbered by the grown-ups.

We have these "penny nails units", but we don't even know for sure the start point. I venture a guess that at some stage, there was a 2d coin (that's tuppence), and it was one inch in diameter, but I don't know.

It would seem that one has to first get past a cost-to-length code conversions to get an actual length dimension, then re-code into AWG or SWG to arrive at the the thickness. 18-gauge gets us to 1.02mm, or 0.403". I can see why folk just get used to whatever AWG fits their gun, and how many pennies long is good for their wood without sticking out the other side

I am still figuring out the nails. I guess it will be awhile before I get to know which nailer best suits me, and whether it shall be air, or cordless electric