-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dro Recommendation For Pm-932?

- Thread starter 38Bill

- Start date

- Joined

- Nov 23, 2014

- Messages

- 2,606

I have a Jet JVM-830 (picture below) and put a www.TPACtools.com 4-axis (vernier on the quill, scale on the Z-axis) DRO on it. Like everyone else with a DRO on a mill, absolutely (and incrementally) love it! Only regret is I didn't do it sooner. In my case the Z-axis is very accurate, but probably depends a lot on the set up. I generally crank the table up just short of the tool, then lightly drop the quill until it touches the work. Zero on the Z-axis, then drop the table to get the tool off the work before moving off the part before the first cut. If I take a 0.050" pass, mic says I took 0.048" - 0.050". I do notice some "wobble" in the Z-axis if I don't lock the table. Usually save that step for my last pass.

TPAC's 4-axis package like mine is $499 with free shipping. You pick the scale length. They come with 5 um (0.0002") resolution glass scales. Your choices from other vendors will be down to 1 um and magnetic scales.

Bruce

TPAC's 4-axis package like mine is $499 with free shipping. You pick the scale length. They come with 5 um (0.0002") resolution glass scales. Your choices from other vendors will be down to 1 um and magnetic scales.

Bruce

- Joined

- May 29, 2014

- Messages

- 188

I have the 932PDF with the QMT supplied 3 axis. I use the X & Y for everything I do on the mill. The Z, virtually never. With the power Z feed, + or - 0.100 inch is about as close as I can get. With the hand crank, quite a bit better; but still nothing to be proud of. I end up using the quill indicator mostly.

From what I have experienced, the Z axis is mostly for bragging rights. Your experience could be totally different.

Jerry in Delaware

From what I have experienced, the Z axis is mostly for bragging rights. Your experience could be totally different.

Jerry in Delaware

- Joined

- Jun 12, 2014

- Messages

- 4,806

Had a BF30 bench top mill for a number of years, go with a 2 axis system and a quill DRO. Never found the need for a 3 axis DRO, unless you use the third axis for the quill (which make installation very challenging and cumbersome if using a glass scale). I had and Acu-Rite 2 axis with a separate vertical quill DRO that worked very nice, but that was back when they were less expensive and Enco had there 20% off sales. Most DRO's these days are quite good, really comes down to features, display and the type of scales you want to use. It is hard to justify the premium for magnetic scales, although they work very nicely and are a bit easier to install then glass scales.

- Joined

- Dec 26, 2015

- Messages

- 2,079

I have a Newall 2-axis DRO on my Rong Fu 45 mill which I love. At the time I bought it, the Newall was the only reasonable option that was impervious to swarf, oil, coolant, etc. with scales small enough to fit a bench mill. I used the microsym scales and encoders on the Newall which are much smaller than the full sized Sym units.

Today, there are other magnetic scale systems that are a bit less expensive that work fine in grit and cutting oil environments. For example, I put a DROpros.com magnetic scale system on my PM1340 lathe and it's fine, although not as refined or thought out as the Newall, but a much better IMO than Shooting Star or similar.

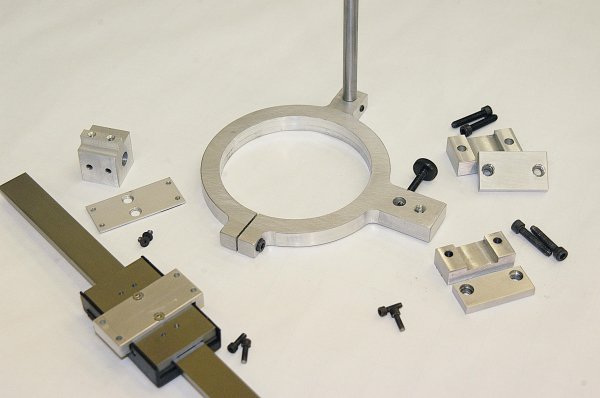

I prefer to have the quill height DRO display on the face of the milling head rather than off on a heads-up display hinged out to the side, so I installed a Mitutoyo scale and fabricated up a quill linkage for it. This Mitutoyo unit is also impervious to oil, although my first attempt used a $40 Asian knock-off that wasn't and it lasted about 2 years and was always eating batteries - the Mitutoyo is much less power hungry and much more robust.

Celebrating completion of Mitutoyo upgrade:

Today, there are other magnetic scale systems that are a bit less expensive that work fine in grit and cutting oil environments. For example, I put a DROpros.com magnetic scale system on my PM1340 lathe and it's fine, although not as refined or thought out as the Newall, but a much better IMO than Shooting Star or similar.

I prefer to have the quill height DRO display on the face of the milling head rather than off on a heads-up display hinged out to the side, so I installed a Mitutoyo scale and fabricated up a quill linkage for it. This Mitutoyo unit is also impervious to oil, although my first attempt used a $40 Asian knock-off that wasn't and it lasted about 2 years and was always eating batteries - the Mitutoyo is much less power hungry and much more robust.

Celebrating completion of Mitutoyo upgrade:

- Joined

- Jan 23, 2016

- Messages

- 18

I've used both Accurite and Newell, both perform well. Personally I like Newell. Newell is well built ,accurate and reasonably priced. Just replaced one our Accurites on a mill very easy to install.

Sent from my LG-D850 using Tapatalk

Sent from my LG-D850 using Tapatalk

I moved an EL700 3 axis DRO sold by DRO Pros from an older mill to my 932 recently. The EL700 has a number of useful programming routines and the ability to use an electronic touch probe. Nice features but you can do lots of work without them. I chose the magnetic scales for ease of installation and resistance to most working conditions.

As with the other posts here found the Z axis readout on the 932 pretty much useless because of the inability of the motor/crank to position the head with any accuracy much beyond .100.

As with the other posts here found the Z axis readout on the 932 pretty much useless because of the inability of the motor/crank to position the head with any accuracy much beyond .100.

- Joined

- Dec 3, 2013

- Messages

- 1,844

The PM-932 comes with a generic scale DRO already installed on the spindle. Before I converted my PM-932 to CNC I found the supplied quill DRO to be adequate (it's now on my drill press). Unless the mill is CNC, raising and lowering the head would not be used for machining, that's what the quill is for. I would never install a scale on the head to column. Unless you want all three axis on the same readout I would just get a 2-axis DRO.