- Joined

- Mar 20, 2013

- Messages

- 153

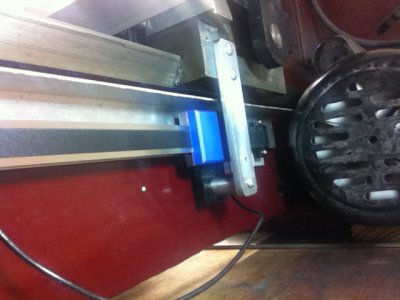

Got my Accuremote DRO scales in from DavidH. Measured them, cut and ground the ends square. Now to start marking, drilling and tapping holes to mount. I see I'm going to need some extensions for the mini USB cables in order to mount them where I want. I noticed that there are a lot of small threaded holes on the back and sides of the reading heads. It looks like some are for gib adjustments but don't know. I emailed DavidH and he will check w the factory/distributor Monday and let me know about the holes. At worst I'll leave as is but could install small screws to fill the holes. I'll post pics later when I have some time.