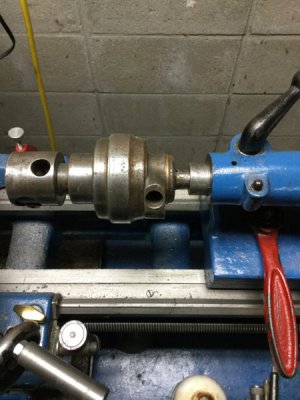

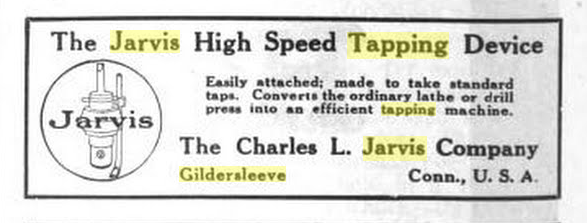

Hello, years ago I bought a Logan Lathe with tooling. The lathe was originally built in 1947. Included in the tooling was an attachment stamped Jarvis Gildersleeve which I believe is used for lathe assisted tapping. I've asked some of the local machinists if they had ever heard of this and no one did. The tool has a Morse taper on one end which apparently goes into the tail stock and a tap chuck on the other end. There is a ratcheting portion, mid tool, with an opening for a threaded rod to operate the ratchet. Operating the ratchet will turn the tap chuck until it extends about 0.75 inches and then further turning will not turn the tap chuck.. I think at this point the tail stock is loosened and advanced towards the headstock. Then repeat the process. I'm guessing at this. Stamped on the body of the tool is :Jarvis Gildersleeve Patent # 1010743. I intend to use it by trial and error method but that is a last resort. I've emailed Jarvis Cutting tools but so far no answer and they may not be the maker of this tool. Any info would be appreciated.

.

.