- Joined

- May 6, 2014

- Messages

- 220

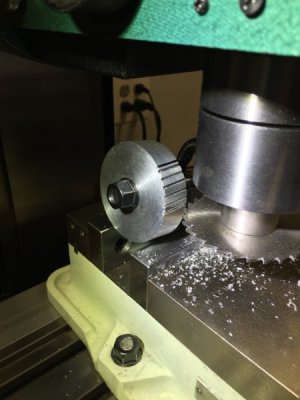

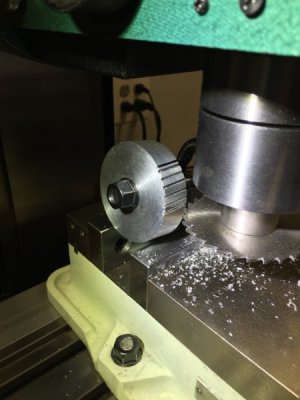

I have been posting my initial efforts in the "what did you do in your shop today" thread, but since I am getting farther along I figured I would put it in my own post. My motivation for making this stems from the fact my milling machine is small and even the poor quality Chinese dividing heads are pretty expensive - plus it seems like a fun project. I am focused on making the critical items first and then will design the rest of the unit around them. The critical items are: the worm/worm gear and the spindle. I've had some good luck with making the worm/worm gear. I've made a hob and tested it out on an aluminum blank. Even though I messed up the orientation of he slots in the gashing operation, it still came out good. I am waiting on getting a piece of brass from my friend to make the final gear. (I'm going with a 40:1 ratio).

Yesterday I figured I would create the final worm (since I still had the gears set-up on the lathe from making the hob). It came out great. I learned something in the process. I was turning the part between centers. Don't try to part off while turning in this manner. Luckily it only slightly marred the edge of the cut when it bent the remaining stump and halted the spindle (belt drives are my friend). Until my brass arrives I am going to work on my spindle. My plan is to kind-of replicate the design of my SB 9C lathe. I want to have the same thread so I can use my existing 3 and 4 jaw chuck plus a faceplate (when I eventually get one). I also have a nice set of 3C collets so I will be boring out the spindle to accept those. I want to be able to use this in the horizontal and vertical orientation, but if that is not doable, I will just make a separate rotary table later- on. I plan to be using some of the ideas that I have seen in some of the other posts on this site as I design this and I'll reference them as I go along.

Yesterday I figured I would create the final worm (since I still had the gears set-up on the lathe from making the hob). It came out great. I learned something in the process. I was turning the part between centers. Don't try to part off while turning in this manner. Luckily it only slightly marred the edge of the cut when it bent the remaining stump and halted the spindle (belt drives are my friend). Until my brass arrives I am going to work on my spindle. My plan is to kind-of replicate the design of my SB 9C lathe. I want to have the same thread so I can use my existing 3 and 4 jaw chuck plus a faceplate (when I eventually get one). I also have a nice set of 3C collets so I will be boring out the spindle to accept those. I want to be able to use this in the horizontal and vertical orientation, but if that is not doable, I will just make a separate rotary table later- on. I plan to be using some of the ideas that I have seen in some of the other posts on this site as I design this and I'll reference them as I go along.