- Joined

- Jul 15, 2020

- Messages

- 421

When I originally started the thread "CNC Plasma When You Have No Space" (https://www.hobby-machinist.com/threads/cnc-plasma-cutting-when-you-have-no-space.85935/) back in August, there appeared to be considerable interest until the $3,000 to $5,000 cost of the process surfaced.

I am just like the next guy out there who admires a big hefty piece of precision machinery. The beefier and heavier a machine is, the more value I generally place on it. While still a big expenditure, many of us have shelled out more than $5,000 for a halfway decent lathe or mill.

In contrast, a small CNC plasma cutting table seems light and flimsy. It's value lies in its capability rather than its mass. When it comes to steel plate 3/8" or thinner, it can do things not possible with any other piece of equipment remotely in its price range. While material up to an inch or more can be cut with a high power plasma cutter, the average home shop can get by fine with a plasma cutter that could plug into a dryer outlet.

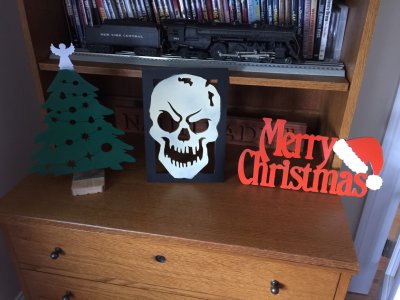

A CNC plasma cutter can produce intricate, detailed shapes with a finish at least as smooth as a bandsaw in perhaps 1/25th of the time. Forget about bandsaw blade welding for inside cuts. Grinding is unnecessary and the small amount of dross generated can be tapped off in a couple of minutes. The time necessary to master the process is less than the time it took you to learn how to use a computer to access this forum.

I urge you to look further into the things you can accomplish with a small CNC plasma table, and place its value on its contributions to your shop rather than its physical impressiveness.

Please understand that I no longer have any commercial interest in selling this stuff, but still have a personal interest in steering others toward this amazing process. Thanks for listening!

I am just like the next guy out there who admires a big hefty piece of precision machinery. The beefier and heavier a machine is, the more value I generally place on it. While still a big expenditure, many of us have shelled out more than $5,000 for a halfway decent lathe or mill.

In contrast, a small CNC plasma cutting table seems light and flimsy. It's value lies in its capability rather than its mass. When it comes to steel plate 3/8" or thinner, it can do things not possible with any other piece of equipment remotely in its price range. While material up to an inch or more can be cut with a high power plasma cutter, the average home shop can get by fine with a plasma cutter that could plug into a dryer outlet.

A CNC plasma cutter can produce intricate, detailed shapes with a finish at least as smooth as a bandsaw in perhaps 1/25th of the time. Forget about bandsaw blade welding for inside cuts. Grinding is unnecessary and the small amount of dross generated can be tapped off in a couple of minutes. The time necessary to master the process is less than the time it took you to learn how to use a computer to access this forum.

I urge you to look further into the things you can accomplish with a small CNC plasma table, and place its value on its contributions to your shop rather than its physical impressiveness.

Please understand that I no longer have any commercial interest in selling this stuff, but still have a personal interest in steering others toward this amazing process. Thanks for listening!

Last edited: