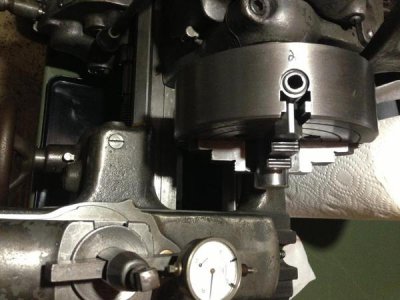

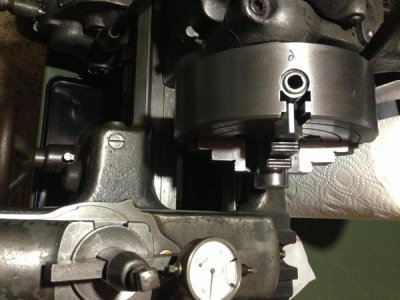

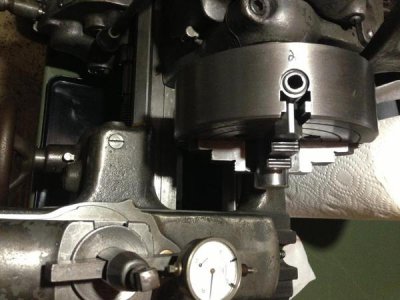

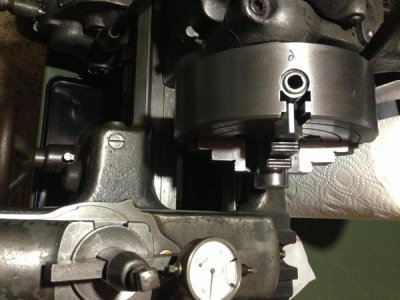

Dial indicator set up for South Bend 9a

Hello,

I recently purchased a South Bend 9 a and need to set up the dial indicator. It is a plunger style indicator that's made in Germany with no manufacturer name.

My question is how can I properly set this up to work in my holder or is this set up not practical to use. Also the indicator sits too high. Here are a few pics.

Hello,

I recently purchased a South Bend 9 a and need to set up the dial indicator. It is a plunger style indicator that's made in Germany with no manufacturer name.

My question is how can I properly set this up to work in my holder or is this set up not practical to use. Also the indicator sits too high. Here are a few pics.

Last edited: