-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dial Indicator Question

- Thread starter Swerdk

- Start date

- Joined

- Feb 8, 2014

- Messages

- 11,144

Not sure how to answer your question. This indicator is not different per se, but the specs are 0.125 range of travel, and 0.0005 divisions. Can be used for pretty accurate measurements within it's range.

- Joined

- Feb 7, 2015

- Messages

- 31

The Starett site says: .125” Range, Dial Reading 0-25-0, .0005” Grad.

I would think for very,very close tight work.

I would think for very,very close tight work.

- Joined

- Feb 1, 2015

- Messages

- 9,559

Different than what? If you are referring to dial vs. test indicator, it has a greater range and you do not have a cosine error because the indicator movement is not exactly perpendicular to the desired measurement path (it sweeps through an arc and the movement can be at a significant angle).Why is this dial indicator different how would i benifit from this

If you are referring to Starrett vs. ?, Starrett is a well known company and has an exceptional reputation in the metrology area. Most dial indicators that you see have .5 or 1 inch travel while this is limited to .125" but its dial graduations are .0005, allowing one to fairly easily estimate to a tenth of a thousandth.

Bob

Last edited:

- Joined

- Feb 8, 2014

- Messages

- 11,144

Why is it with positive and negative side when dial only goes clockwise twds positive?

Can i use this as a soft stop to measure carriage distance if it was set up as a distance measuring device? Most dials i have seen go from 0-90.

You would normally preload the indicator to the ''0'' point, then take measurements from that point, thus the +/- graduations.

You could use it as s soft stop. Set the desired stop point at 0 then move to that 0 point each time.

- Joined

- Feb 1, 2015

- Messages

- 9,559

The dial can be rotated to whatever position you desire. Typically, you would pre-load the indicator to some position midway in the travel range and zero the indicator. You will then be able to measure in both directions.Why is it with positive and negative side when dial only goes clockwise twds positive?

Can i use this as a soft stop to measure carriage distance if it was set up as a distance measuring device? Most dials i have seen go from 0-90.

You can set it up to measure soft stop position. Set your stop up at about a .025" deflection and set your zero point there. Or just decide to stop when you hit some number, say .010". A minimum setting will give you the maximum safety margin should you overshoot.

Bob

- Joined

- Jan 2, 2014

- Messages

- 8,848

Hi Swerdk,

If you go thru the Starrett website to choose an indicator here:

http://www.starrett.com/metrology/m...isplayMode=grid&itemsPerPage=24&sortBy=wp/asc

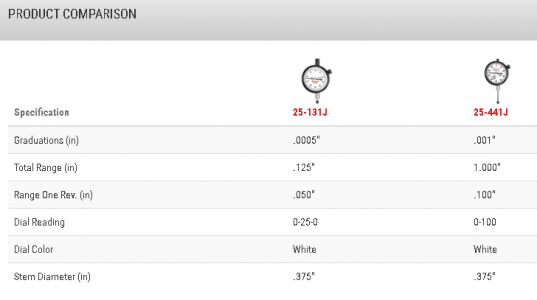

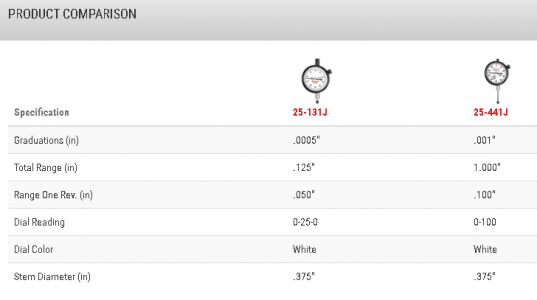

and select 0.0005" for Graduations and 0.125" for Total Range, you'll see they offer that indicator with either a "0-25-0" or "0-50" scale.

Compare it to this one:

http://www.starrett.com/metrology/p...tors-and-Gages/110503-Dial-Indicators/25-441J

that is graduated in thousandths (0.001") and has a range of 1 inch.

The Starrett site has a compare feature that lets you choose different products and pull up all relevant info on one page, like this:

One limitation of that indicator is its very small range. Notice how little of the stem is sticking out of the body?

You can only get 0.125" inch travel that's only 1/8 inch full range from it!

It is very accurate, but has a very small range.

It could be used for a soft stop, but really only useful for that if you are measuring less than 1/8" between features.

It is still useful, but I'd think more useful for closely checking for spindle run out, where you will (hopefully) be dealing with small numbers and very limited range.

-brino

If you go thru the Starrett website to choose an indicator here:

http://www.starrett.com/metrology/m...isplayMode=grid&itemsPerPage=24&sortBy=wp/asc

and select 0.0005" for Graduations and 0.125" for Total Range, you'll see they offer that indicator with either a "0-25-0" or "0-50" scale.

Compare it to this one:

http://www.starrett.com/metrology/p...tors-and-Gages/110503-Dial-Indicators/25-441J

that is graduated in thousandths (0.001") and has a range of 1 inch.

The Starrett site has a compare feature that lets you choose different products and pull up all relevant info on one page, like this:

One limitation of that indicator is its very small range. Notice how little of the stem is sticking out of the body?

You can only get 0.125" inch travel that's only 1/8 inch full range from it!

It is very accurate, but has a very small range.

It could be used for a soft stop, but really only useful for that if you are measuring less than 1/8" between features.

It is still useful, but I'd think more useful for closely checking for spindle run out, where you will (hopefully) be dealing with small numbers and very limited range.

-brino

- Joined

- Jan 22, 2011

- Messages

- 8,031

You'll see indicators like this typically on dial bore gages. Mechanically, they don't have more travel in their mechanism than 0.025, so no need of more in the indicator part. Bore gages of this type are generally set with plain ring gages to a specific diameter. They then can be read using + or - tolerance ranging, or +0.xxxx/-0.0000, or +0.0000/-0.xxxx