- Joined

- Mar 10, 2015

- Messages

- 309

Alright tool junkies can use your help wanted to bounce this off yall . I received this gauge from a friend who wants me to sell it on e bay for him. I dont like misunderstanding and wouldn't want to sell something without properly listing it . ( guess cuz i dont get it yet)

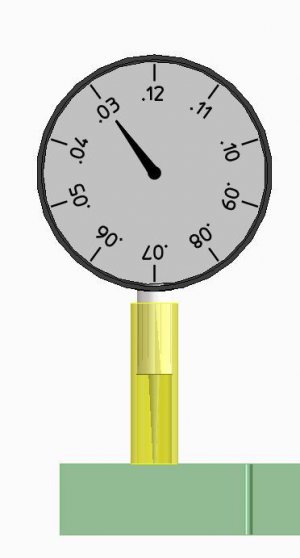

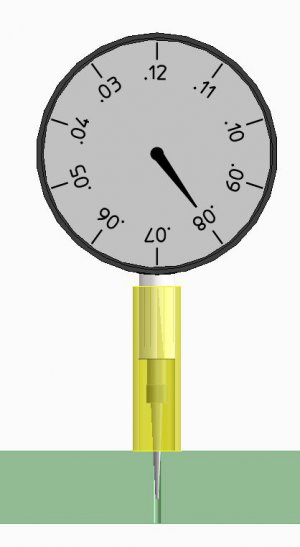

Its a Brencor Inc (Dyer Company) Dial Hole Check Gage Model 500-010. I looked on the website and found no such detailed instructions. As you see it does have instructions however something I dunno why I dont get YET.. Like duh! Help me see this please prob real simple too... Lol

It seems to have One inch travel yet the increments show otherwise (.010) Maybe its just me but how do you measure with this gauge .? Is it meant to use only with a a bore gauge set to proper diam. Reading in positive direction? And how does that correspond with divisions and travel?

The prob i have is a bit of a stumbling block here . Any one like to help me get the picture . Please have a look at divisions in pic they are .010 div yet it seems like it is .100 travel . ??

TIA for any confirmation .

Its a Brencor Inc (Dyer Company) Dial Hole Check Gage Model 500-010. I looked on the website and found no such detailed instructions. As you see it does have instructions however something I dunno why I dont get YET.. Like duh! Help me see this please prob real simple too... Lol

It seems to have One inch travel yet the increments show otherwise (.010) Maybe its just me but how do you measure with this gauge .? Is it meant to use only with a a bore gauge set to proper diam. Reading in positive direction? And how does that correspond with divisions and travel?

The prob i have is a bit of a stumbling block here . Any one like to help me get the picture . Please have a look at divisions in pic they are .010 div yet it seems like it is .100 travel . ??

TIA for any confirmation .

Last edited: