I am putting this small project here instead of the lathe forum because although mine is a south bend , I think this can be adapted easily to any lathe. I need to index my lathe chuck sometimes so I whipped up this degree wheel this afternoon for something I was working on. It only took a couple hours to make.

I started with a degree wheel I downloaded from the internet and printed it out at 8 inches in diameter (because that is the widest paper my printer will handle). I scavenged a .100" thick white plastic sheet from an old scanner I was throwing away. I cut it a little larger than 8 inches in diameter with a utility knife.

I next glued the degree wheel I printed on a piece of photo paper. I used photo paper because it is shiny and more durable ( I like shiny things) .

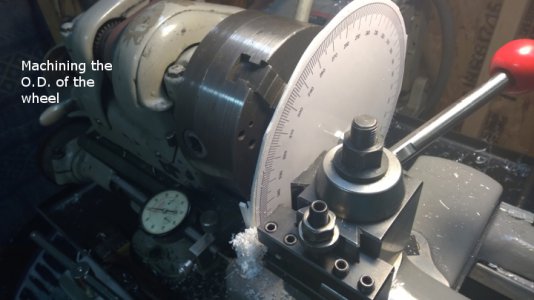

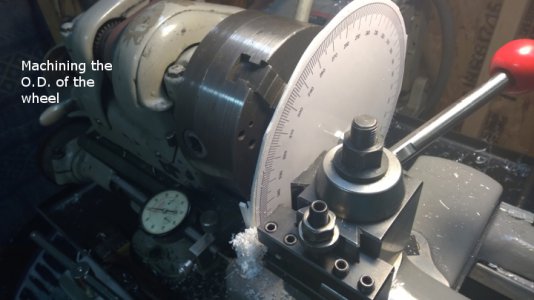

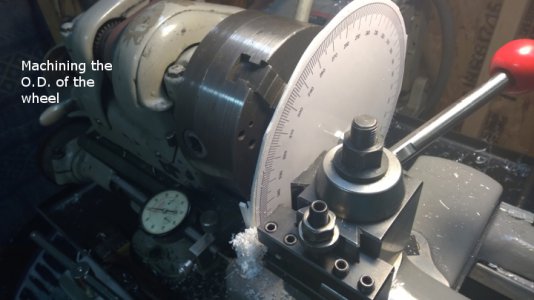

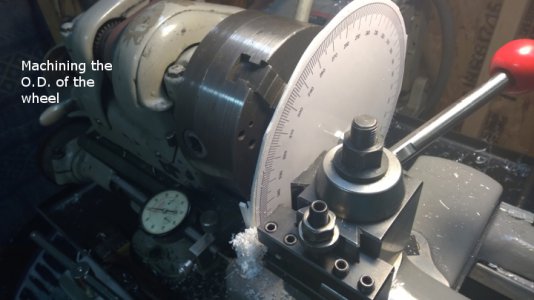

I made an aluminum hub that fit on the back of my lathe spindle. It is held on with a brass thumb screw I made earlier. I drilled a 1/4" hole in the hub and the center of the disc and bolted them together. Then mounted the hub in the chuck and GENTLY turned the O.D. of the disc.

The completed disc mounts on and off the spindle in seconds and being 8 inches in diameter it gives very good accuracy for indexing the spindle.

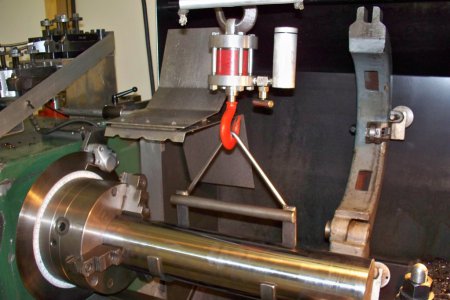

I have a pointer (not shown here) that is a magnetic block with a pointer fixed on it and I just stick it to the bearing housing.

It is cheap and easy but works just fine. My goal is to find an 8 inch aluminum disc to make one out of.

Mark Frazier

I started with a degree wheel I downloaded from the internet and printed it out at 8 inches in diameter (because that is the widest paper my printer will handle). I scavenged a .100" thick white plastic sheet from an old scanner I was throwing away. I cut it a little larger than 8 inches in diameter with a utility knife.

I next glued the degree wheel I printed on a piece of photo paper. I used photo paper because it is shiny and more durable ( I like shiny things) .

I made an aluminum hub that fit on the back of my lathe spindle. It is held on with a brass thumb screw I made earlier. I drilled a 1/4" hole in the hub and the center of the disc and bolted them together. Then mounted the hub in the chuck and GENTLY turned the O.D. of the disc.

The completed disc mounts on and off the spindle in seconds and being 8 inches in diameter it gives very good accuracy for indexing the spindle.

I have a pointer (not shown here) that is a magnetic block with a pointer fixed on it and I just stick it to the bearing housing.

It is cheap and easy but works just fine. My goal is to find an 8 inch aluminum disc to make one out of.

Mark Frazier