Hello,

I am vaguely aware of various methods used to cut HSS tool blanks

1. Notch the hss on the corner of grinding wheel, put in vice, cover with rag, tap with hammer

2. Some sort of abrasive wheel in a dremel - I tried this and the wheel wore away to nothing, very quickly, in a 1/4 hss blank

3. Very thin wheel on a bench grinder ? Keywords for this type of wheel ?

4. Very thin wheel on an angle grinder ? Keywords for this type of wheel ?

5. This morning I was able to use an el cheapo diamond blade in the dremel - worked very well

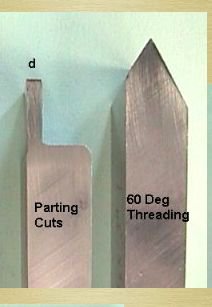

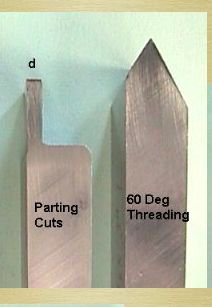

6. Carbide parting tool on lathe ? Not sure about this one - anybody done it ?

Is there a way I havent listed ?

Bill

I am vaguely aware of various methods used to cut HSS tool blanks

1. Notch the hss on the corner of grinding wheel, put in vice, cover with rag, tap with hammer

2. Some sort of abrasive wheel in a dremel - I tried this and the wheel wore away to nothing, very quickly, in a 1/4 hss blank

3. Very thin wheel on a bench grinder ? Keywords for this type of wheel ?

4. Very thin wheel on an angle grinder ? Keywords for this type of wheel ?

5. This morning I was able to use an el cheapo diamond blade in the dremel - worked very well

6. Carbide parting tool on lathe ? Not sure about this one - anybody done it ?

Is there a way I havent listed ?

Bill