- Joined

- Jan 4, 2024

- Messages

- 22

I’m not sure if this is the correct place to ask this, if not I’m sure the moderators will move it appropriately.

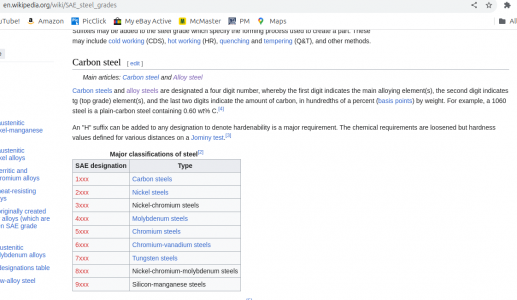

I need to repair the rocker part of my patio chairs, They’re manufactured using two 4 1/2 x 2 1/2 x 1/4 fiberglass plates to provide the rocking motion. Obviously they deteriorate quickly so give a very insecure feeling when you rock. I was thinking about using spring steel to replace them. Its 5160 alloy steel from McMaster-Carr but its hardness is C25, I have no idea what that means. Will I be able to cut and drill it or is there a better idea?

Thank you

I need to repair the rocker part of my patio chairs, They’re manufactured using two 4 1/2 x 2 1/2 x 1/4 fiberglass plates to provide the rocking motion. Obviously they deteriorate quickly so give a very insecure feeling when you rock. I was thinking about using spring steel to replace them. Its 5160 alloy steel from McMaster-Carr but its hardness is C25, I have no idea what that means. Will I be able to cut and drill it or is there a better idea?

Thank you