-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

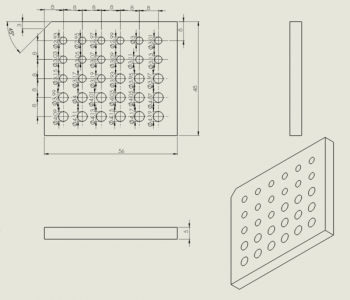

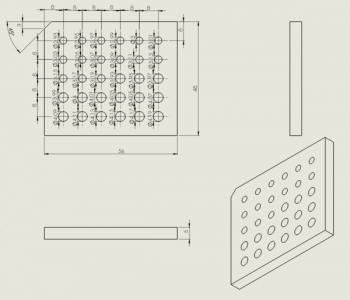

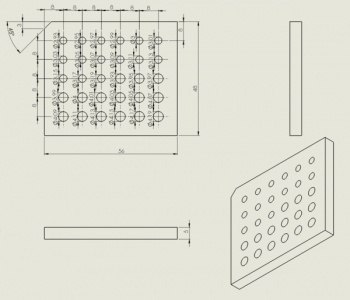

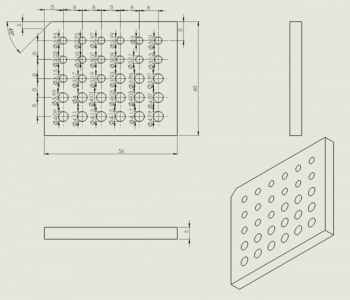

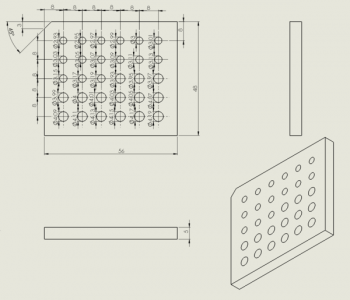

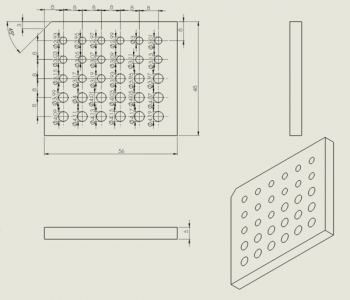

[Newbie] Cutting A Nylon Part With Many Different Holes

- Thread starter mun

- Start date

- Joined

- Jul 2, 2014

- Messages

- 7,594

To make different sized holes you should use an end mill rather than a drill, and orbit the tool for the different sizes. I am not a CNC guy, so cannot really comment on the difficulty of the project. It looks pretty straightforward, but a lot of details are left out, like what material and thickness it is made from. Tolerances as well...

Edit: Welcome to Hobby-Machinist!

Edit: Welcome to Hobby-Machinist!

- Joined

- Jun 12, 2014

- Messages

- 401

Easily made, yes. As Bob said, you should use an endmill and interpolate the holes within your programming.

- Joined

- Jan 20, 2016

- Messages

- 1,011

0.02mm = less than 8/10,000 of an inch. That kind of accuracy might be pushing a some (bench-top or well used) CNC mills. Tool wear and tool run-out will have to be carefully accounted for. The end mill would have to be around 0.10" for the smaller holes which in turn might require a high speed spindle - depending on material (and like someone said before - nylon probably will not hold those dimensions).

Not hard to do, but there are a few things one is not normally concerned about. I make aluminum emblems/badges and regularly hold tolerances of 0.005" using end mills as small as 0.015" using a modified bench-top CNC mill.

Not hard to do, but there are a few things one is not normally concerned about. I make aluminum emblems/badges and regularly hold tolerances of 0.005" using end mills as small as 0.015" using a modified bench-top CNC mill.