Howdy! I acquired a LMS-3540 (I think?...might be the 3536 but I can't tell for certain) which is based on the Sieg SC4. After practicing turning and facing for a few hours, I decided to crack into the change gears and figure out threading. This lathe doesn't have a thread dial indicator, so the only way to cut threads is to stop & reverse the spindle. It was a bit harrowing but going at the slowest speed wasn't too bad.

I decided to try making some 1/2x28 threads, since I had a loose flash-hider hanging around. Turns out this lathe has difficulties cutting threads this fine. I managed to wiggle things around such that there was only minor rubbing between the C gear and the spindle gear end cap. It seemed acceptable to me when running at the minimum spindle RPM.

After turning down a ~0.600" long section of the rod to an outer diameter of just under 0.500", I used a parting blade to cut a bit of a thread relief. Then a 60-degree carbide insert to do the threading.

It was a huge success! After watching machining videos and reading forum posts like the afore-mentioned one for the last few years, I felt that I was pretty prepared and didn't really run into any issues, aside from the gears not fitting.

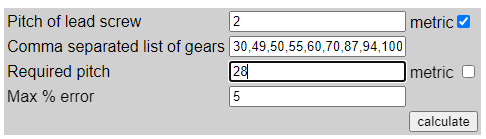

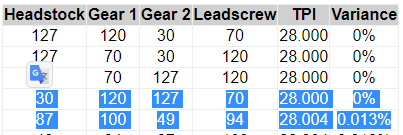

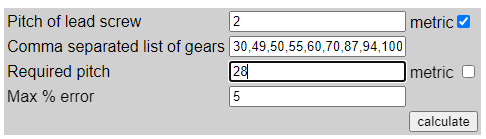

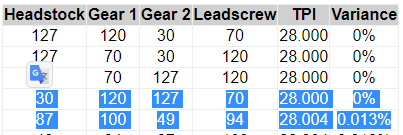

For anyone else using the SC4/LMS-3540/LMS-3536, LittleMachineShop.com sells a set of change gears for the HiTorque 8.5x16 (3536) and 8.5x20 (3540) lathes. They also have a 4-page threading guide which provides alternate gear combinations using this specific gear set. The gear combo in this guide (49, 94, 87, 100) results in 28.004 TPI threads, which resulted in ~0.013% error. I ordered a set of these gears to play around with to determine if this type of error is acceptable or not, generally-speaking. Using the original gears (30, 120, 127, 70) results in exactly 28 TPI, but the gears don't quite fit. See below results from http://bilar.co.uk/cgi-bin/change-gear-calculator.pl (AFAIK the SC4-based lathes have a 2mm lead screw):

I think that's all I have to say. I just wanted to record my experiences here for posterity in the event that others using the same lathes have similar questions/concerns as I had.

Thanks for reading!

I decided to try making some 1/2x28 threads, since I had a loose flash-hider hanging around. Turns out this lathe has difficulties cutting threads this fine. I managed to wiggle things around such that there was only minor rubbing between the C gear and the spindle gear end cap. It seemed acceptable to me when running at the minimum spindle RPM.

After turning down a ~0.600" long section of the rod to an outer diameter of just under 0.500", I used a parting blade to cut a bit of a thread relief. Then a 60-degree carbide insert to do the threading.

It was a huge success! After watching machining videos and reading forum posts like the afore-mentioned one for the last few years, I felt that I was pretty prepared and didn't really run into any issues, aside from the gears not fitting.

For anyone else using the SC4/LMS-3540/LMS-3536, LittleMachineShop.com sells a set of change gears for the HiTorque 8.5x16 (3536) and 8.5x20 (3540) lathes. They also have a 4-page threading guide which provides alternate gear combinations using this specific gear set. The gear combo in this guide (49, 94, 87, 100) results in 28.004 TPI threads, which resulted in ~0.013% error. I ordered a set of these gears to play around with to determine if this type of error is acceptable or not, generally-speaking. Using the original gears (30, 120, 127, 70) results in exactly 28 TPI, but the gears don't quite fit. See below results from http://bilar.co.uk/cgi-bin/change-gear-calculator.pl (AFAIK the SC4-based lathes have a 2mm lead screw):

I think that's all I have to say. I just wanted to record my experiences here for posterity in the event that others using the same lathes have similar questions/concerns as I had.

Thanks for reading!

Last edited: