- Joined

- Mar 2, 2013

- Messages

- 895

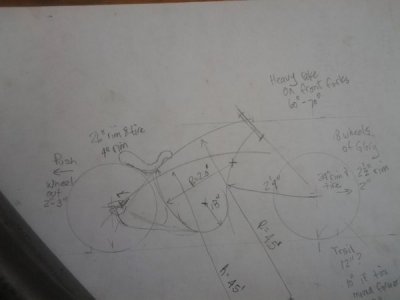

i've built a couple beach cruisers, roach cruisers, customs, board track racers. Its how i got into machining, I am certainly not the person to talk to if you are looking for a traditional bike, but if you want something outside the box, i've hacked together a couple frames. Cro Moly is a good choice, easy to work with, strong, light, and forgiving. .065 ga is common, some go lighter, some heavier. .065 works nice in a manual tubing bender, I've used mine to make bends for the front forks, and the rear. The above mentioned harbor freight tubing roller makes nice sloping tubing that woks well for the main frame. With the use of a lathe of moderate size you can make your own custom head tubes to accommidate any head bearings...

making rear rims from cars into bike tires is slick, motorcycle tires are rounder on the sides so they are easier to lean than the squarer profile of a car tire. something to consider when making a rim selection

hth

rich

making rear rims from cars into bike tires is slick, motorcycle tires are rounder on the sides so they are easier to lean than the squarer profile of a car tire. something to consider when making a rim selection

hth

rich