- Joined

- Sep 23, 2010

- Messages

- 619

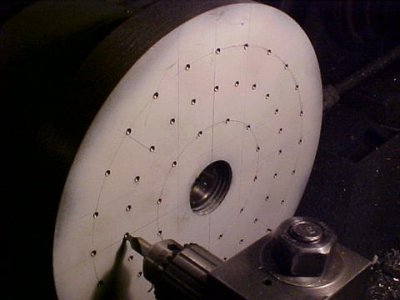

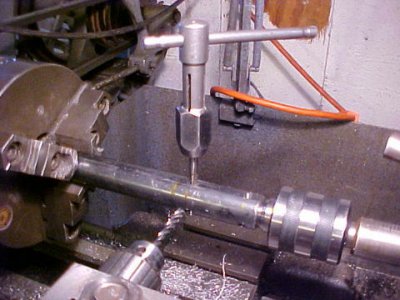

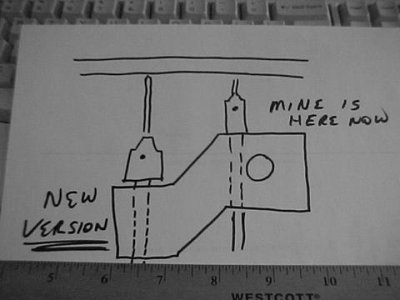

Here is something i use all the time to drill holes like set screw holes in a shaft without removing the part from the lathe. I used it making my lathe ball turner and it saved some time from removing the part, drilling it then trying to get everything lined up true in the lathe again. I also used it combined with my spindle end degree wheel to layout and center drill my large faceplate i turned. Then i finished drilling the holes in my drillpress. Today i did a small job that came in the guy (my dad) wanted 2 holes drilled in his shotgun barrel and they were crooked plus inside a ring. I just chucked up the barrel and used a steady on the other end. Turned it where the center line was, swapped my tool post for my hole driller, spotted the first hole, changed bits and drilled it. Then repeted the operation for the 2nd hole. He said the last time his buddy did one in his mill they broke 6 1/8" bits. I had zero problems and it shoots just fine. Here are a couple of pics and i have some more...Bob

![6dc5[1].jpg 6dc5[1].jpg](https://www.hobby-machinist.com/data/attachments/0/321-d647f2e85025bb638d7a04d0c4a2472f.jpg)

![6dc5[1].jpg 6dc5[1].jpg](https://www.hobby-machinist.com/data/attachments/0/321-d647f2e85025bb638d7a04d0c4a2472f.jpg)

Last edited by a moderator: