- Joined

- Nov 27, 2016

- Messages

- 13

Hi all, just joined the forums, and I had a question for other Criterion boring head owners out there.

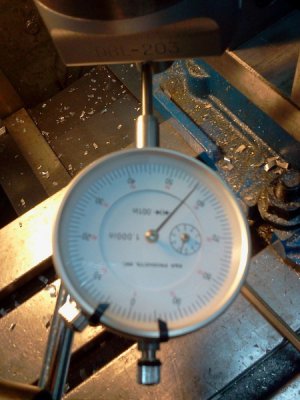

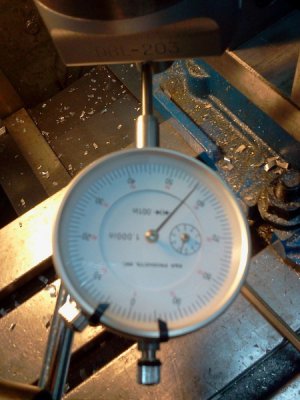

I just picked up a Criterion DBL-203 3" boring head on eBay. It appeared to be in excellent condition, so I went for it, and when I put it in my mill, it looked a little off to me. So I got the dial indicator out, and checked a few things. Not thrilled with what I found. The whole boring head seems to be offset about .016" or so at the tool holder. I put a piece of ground .75" in the center holder and centered slide so I wasn't reading offset in that direction, and it has about .016 of deviation perpendicular to the slide direction.

I took it off the R8 arbor, and couldn't find anything wrong. I put a dial indicator on the face of the arbor where the boring head snugs against it, and it was square as could be. I couldn't figure out how to accurately measure the location of the 1.5 x 18 threads, i.e. if they were centered with the spindle or not, but just looking at them, they don't appear to be off center by .016.

So the best I can figure is that the boring head's female threads are off center?! Anyone else with a Criterion want to measure theirs and see if it's similar in any way? Should I just not worry about this?

Here's my measuring setup.

Here's the set screw/gib side. (Sorry for the awful photo)

And here's the other side.

Thanks in advance for everyone's help.

Edit: fixed the pictures.

I just picked up a Criterion DBL-203 3" boring head on eBay. It appeared to be in excellent condition, so I went for it, and when I put it in my mill, it looked a little off to me. So I got the dial indicator out, and checked a few things. Not thrilled with what I found. The whole boring head seems to be offset about .016" or so at the tool holder. I put a piece of ground .75" in the center holder and centered slide so I wasn't reading offset in that direction, and it has about .016 of deviation perpendicular to the slide direction.

I took it off the R8 arbor, and couldn't find anything wrong. I put a dial indicator on the face of the arbor where the boring head snugs against it, and it was square as could be. I couldn't figure out how to accurately measure the location of the 1.5 x 18 threads, i.e. if they were centered with the spindle or not, but just looking at them, they don't appear to be off center by .016.

So the best I can figure is that the boring head's female threads are off center?! Anyone else with a Criterion want to measure theirs and see if it's similar in any way? Should I just not worry about this?

Here's my measuring setup.

Here's the set screw/gib side. (Sorry for the awful photo)

And here's the other side.

Thanks in advance for everyone's help.

Edit: fixed the pictures.

Last edited: