H

Hukshawn

Forum Guest

Register Today

What kind of lathe do you have ? Is it a imperial or metric lead screw? How far past the beginning of the thread lead are you coming to allow the lead screw to take up any backlash that may be present, and I cant be sure but I would bet there will be some. Is there a quick change gearbox or do you have change gears? Are they set for imperial ( TPI ) threading ? I ask this because that was my trouble when learning to thread , I would get the first scratch pass down and looked good. Returned the carriage to the start watched for the thread dial to come around and whamo it would cut right beside the first thread. Lots of unanswered questions here, lots of good advice but missing info to get to the root of your trouble.

the lathe is an Enterprise 10. made in india. cant find a whole lot of info on it.

no idea what the lead screw is, how would i find that out?

i had been going about 1/4" past the work piece and letting it travel back to take up the slack.

yes, quick change gear box.

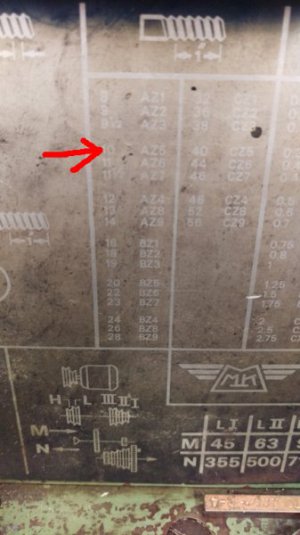

set to what you see in the photos. i really hope its just an error in operation... cause i was really hoping this lathe would be a keeper...

edit. let me elaborate a bit more... i had initially been trying to cut at 18tpi. i set it to 10 to do a few tests once i posted here. figured a wide thread would show the issues better.