- Joined

- Jul 14, 2013

- Messages

- 198

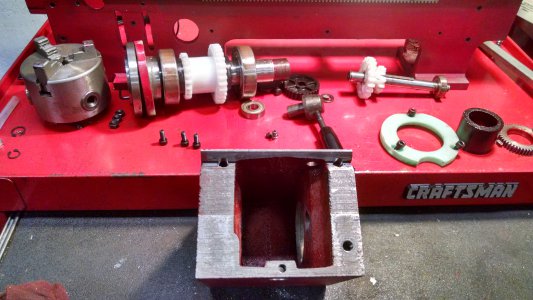

While pushing the limits on a recent project, I crashed the toolpost into the chuck... CRUNCH!

The grinding and chatter in the headstock meant a teardown and repair was in order, so why not upgrade?

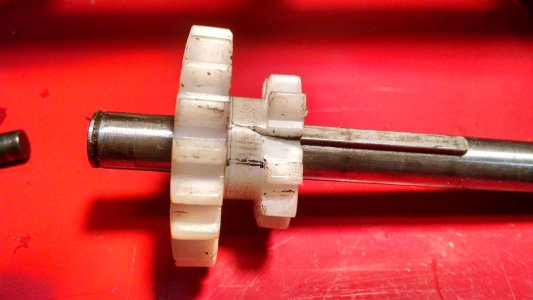

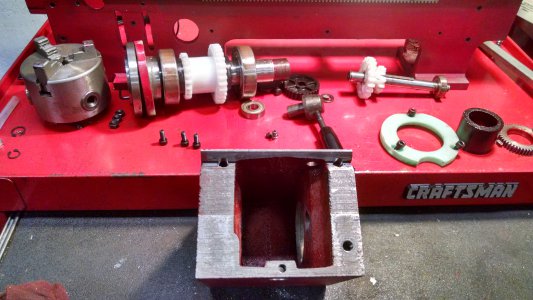

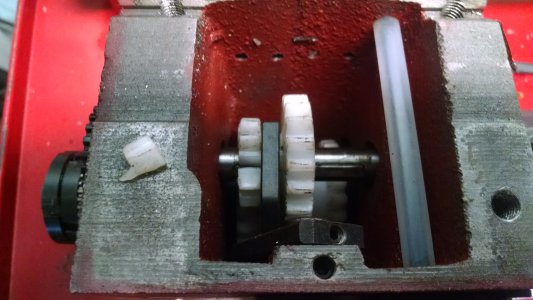

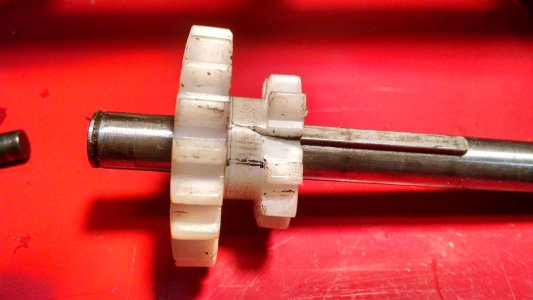

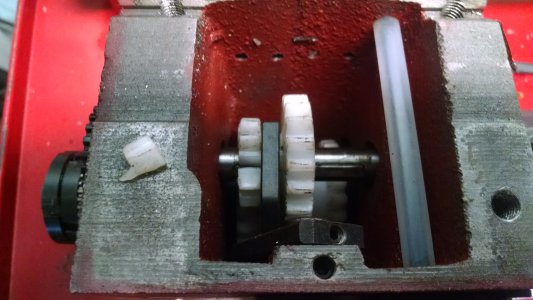

The teardown confirmed my suspicions: plastic transmission gears....

So... here's my current set of upgrades:

16" Bed from LMS (a full 8" longer than the alleged 10")

Metal transmission gear set from LMS

Plastic -vs- metal gear set

the following are some of the teardown pics:

The grinding and chatter in the headstock meant a teardown and repair was in order, so why not upgrade?

The teardown confirmed my suspicions: plastic transmission gears....

So... here's my current set of upgrades:

16" Bed from LMS (a full 8" longer than the alleged 10")

Metal transmission gear set from LMS

Plastic -vs- metal gear set

the following are some of the teardown pics: