- Joined

- Nov 18, 2012

- Messages

- 1,352

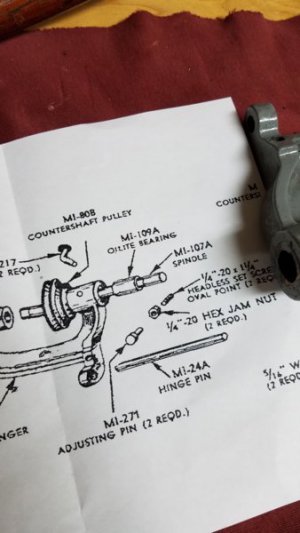

By looking at your pulleys there either worn badly or the belt needs to be wider 5/8" instead of 1/2". The red belt is riding way to low in the pulley . The flat of the belt should be level or a tiny bit above the pulley. Just my observation of the set up.

Good observation. I wonder if the belt is riding on the bottom of belt rather than the sides? And hence the need for way too much belt tension.

David