-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

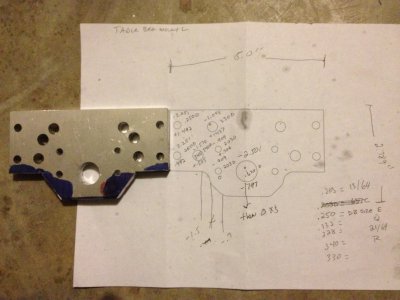

Copycat Mill Build.

- Thread starter Blackhawk

- Start date

- Joined

- Apr 30, 2012

- Messages

- 2,401

should not hurt anything, did you compare my measurements to your mill

who knows if they are all drilled the same? the alignment pin holes are drilled after assembly i guess because they are not in the same locations on my mill table. so i did not install the pins

steve

who knows if they are all drilled the same? the alignment pin holes are drilled after assembly i guess because they are not in the same locations on my mill table. so i did not install the pins

steve

- Joined

- Jul 7, 2012

- Messages

- 641

I think i will order this, cant go wrong for .54

http://www.winfordeng.com/products/con15.php

lanham

If you need it urgently, you can walk into Radio Shack and get a 15 or 25 pin D-Sub connector, plug, or hood for about $2 each.

M

I made the mistake of not removing an endmill from the spindle while setting up a part in the vice. Ran my fist into (spindle was off). Cut me pretty good. They cut people even better than aluminum...

Also, shielded cable is good, but you need to make sure you ground your shield properly, or it doesn't do you any good. Usually there is what is called a "drain wire"; a bare wire that runs through the length of the cable and sits against the metal shield. Tie this to earth ground. Don't tie it to your power supply negative, that can just make things worse.

Also, shielded cable is good, but you need to make sure you ground your shield properly, or it doesn't do you any good. Usually there is what is called a "drain wire"; a bare wire that runs through the length of the cable and sits against the metal shield. Tie this to earth ground. Don't tie it to your power supply negative, that can just make things worse.

Steve,

I checked the measurements before i started making brackets and it looks like it will fit.

I got 100 feet of shielded wire from the same place as you.

Do you have the demensions for the side brackets? I did not see them in the zip file from your build?

7HC,

I ordered the parts i needed for the controller from online, not bad for .54 but $6.oo shipping was high.

Dms,

thanks for the tip on the ground wire.

off to make more brackets.

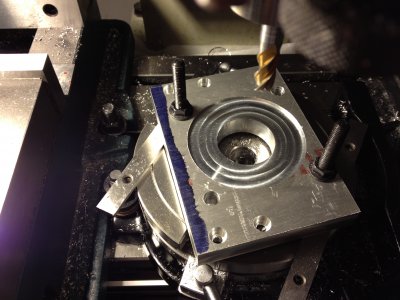

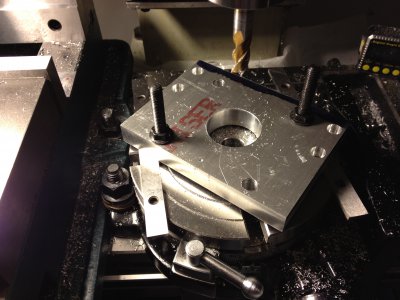

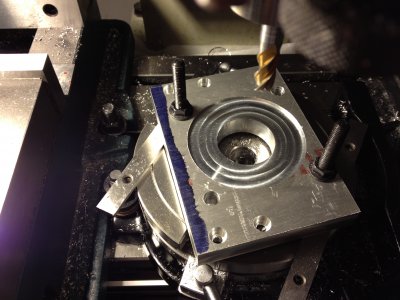

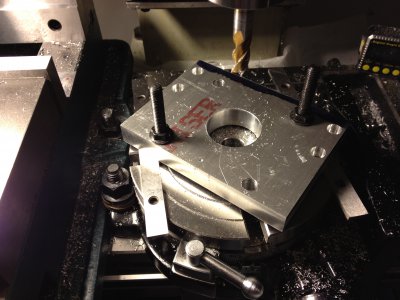

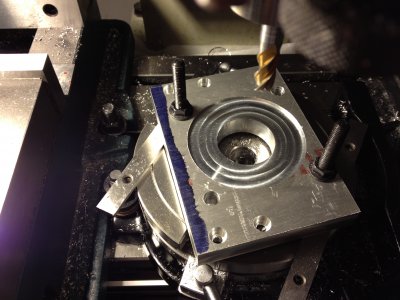

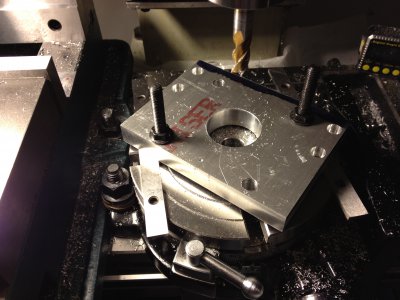

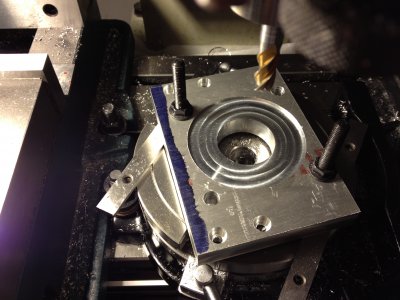

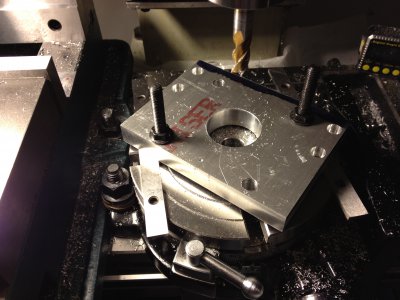

This is the first time i have used a rotary table and jacked it up a bit.

I checked the measurements before i started making brackets and it looks like it will fit.

I got 100 feet of shielded wire from the same place as you.

Do you have the demensions for the side brackets? I did not see them in the zip file from your build?

7HC,

I ordered the parts i needed for the controller from online, not bad for .54 but $6.oo shipping was high.

Dms,

thanks for the tip on the ground wire.

off to make more brackets.

This is the first time i have used a rotary table and jacked it up a bit.

- Joined

- Apr 30, 2012

- Messages

- 2,401

I'm headed for the shed now

I will measure the side brackets/standoffs and post them this morning

there was no drawing because none of the machining was cnc

the coupling length makes a difference in the standoff length i will post my coupling lengths also

your moving right along

steve

I will measure the side brackets/standoffs and post them this morning

there was no drawing because none of the machining was cnc

the coupling length makes a difference in the standoff length i will post my coupling lengths also

your moving right along

steve