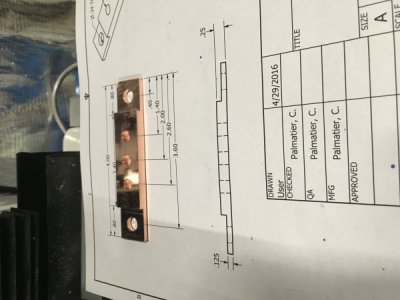

Its week two with the new PM-25 mill, and I have already worked with 1018 CR, and 6x and 7x Aluminium. I'm still feeling the machine out, but I already took on a small project making a bus bar for a PT-17 Boeing Stearman that I've been helping to build. Simple enough design, but now on to the questions.

I've read that copper is a nightmare, but so far I have been having very little issue following techniques similar to to milling aluminum. I'm actually working dry, with a 1/2" 2 flute TiAlN EM at 1500 RPM's. I have been working with a DOC of 0.10-0.20" and a fairly slow feed rate to attempt to produce a good surface finish.

Am I just getting lucky with the set up? Brand new sharp cutters I feel could be masking improper milling parameters/techniques. I don't have a lube/coolant mist set up yet - mostly because I'm worried about the mess (this is in my house) - so once I tackle containment, this will be next.

What tips does the group have on working with soft metals such as copper (in this case 110 copper).

In my hunt I have come across and interesting document, but feel like it is also kind of an argument to use copper as more of an everyday material.

http://copperalliance.org.uk/resource-library/machining-brass-copper-and-copper-alloys362

-IM

I've read that copper is a nightmare, but so far I have been having very little issue following techniques similar to to milling aluminum. I'm actually working dry, with a 1/2" 2 flute TiAlN EM at 1500 RPM's. I have been working with a DOC of 0.10-0.20" and a fairly slow feed rate to attempt to produce a good surface finish.

Am I just getting lucky with the set up? Brand new sharp cutters I feel could be masking improper milling parameters/techniques. I don't have a lube/coolant mist set up yet - mostly because I'm worried about the mess (this is in my house) - so once I tackle containment, this will be next.

What tips does the group have on working with soft metals such as copper (in this case 110 copper).

In my hunt I have come across and interesting document, but feel like it is also kind of an argument to use copper as more of an everyday material.

http://copperalliance.org.uk/resource-library/machining-brass-copper-and-copper-alloys362

-IM