I am a Woody that has taken up metalwork. I have a Lathe and Mill but no machine to cut stock steel etc.

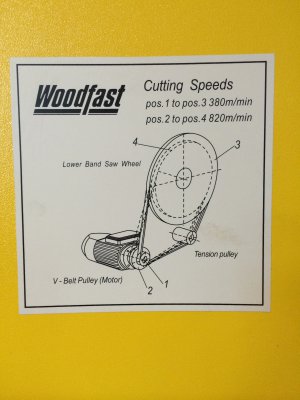

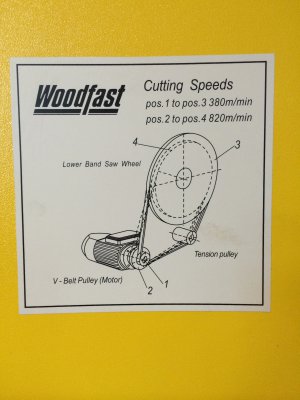

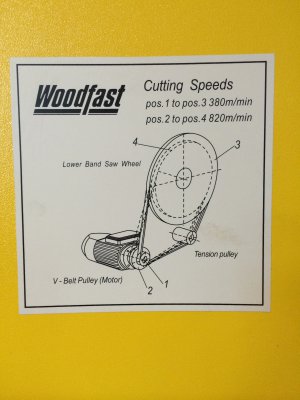

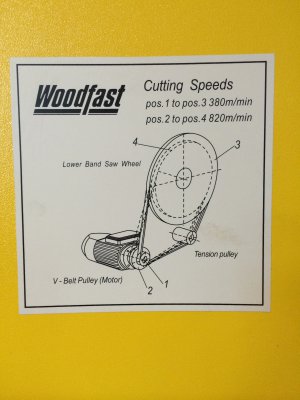

My wood vertical bandsaw ( a Woodfast 19" model of Chinese origin) has a two speed belt transmission and runs at 1246 or 2690 FPM ( 380 or 820 M/min)

Even the lower speed is much too fast for steel cutting which has a recommendation of around 100FPM or 30-40 M/min.

I overcame the problem by removing the original 2Hp single phase 1400rpm motor and replacing it with a second hand flange mount 3 Phase 4 pole 3 Hp 1440 rpm motor. 2nd hand 3 phase motors are available very cheaply on eBay in Australia. In retrospect a 6 pole motor that runs around 900 rpm would give even slower cutting speeds. Alternatively a smaller pulley on the motor may be possible which can be compensated for when cutting wood by setting the VFD to boost the speed

.

I then fitted a second hand Allen Bradley 1305 2.2 Kw VFD with the Control Panel removed. ( many VFD's allow you to remove the control panel and mount it externally on an extension cord). This particular Allen Bradley VFD is an older model, readily available 2nd hand fairly cheaply, and from my experience pretty bullet proof. Also there are many Chinese versions available on eBay. VFD's are available to run off single or three phase supply whichever suits your workshop.

VFD mounted on back of Bandsaw under table. Out of the way and out of the swarf.

The VFD Control panel was mounted on the front of the Bandsaw for ease of control. It is used to start, stop and adjust the speed of the saw. The control panel has a button for reversing the motor but for safety reasons this was locked out in the software. The VFD allows me to run the saw from 10 to 60 Hz (124 to 300FPM). A 6pole motor would have allowed speeds down to about 90 fpm

It will actually go up to 400Hz but this is not recommended for either the saw or the motor and has been limited in the programming of the VFD. The next photo shows the motor running at 10 Hz with plenty of torque to cut 1" steel.

I tested by cutting through 1" steel rod. Progress was remarkably good, faster than I had imagined and the band saw never lacked power. VFD's have the capacity to boost current and hence power at low speeds. The bandsaw blade I used was a Starrett Carbon Steel 1/2" 14tpi Raker Set and it produced a very smooth cut even used without coolant.

I was worried that slowing the motor to 10 Hz would also slow the motor cooling fan, causing it to overheat. My tests so far seem to indicate that there is no problem. The power required to cut the 1" steel rod was so low that the 3 Hp motor didn't even get warm. Extended cutting may turn up a problem but I don't think it will be an issue for the amount of steel I cut.

The beauty of the system is that the saw will still cut brass, aluminium and wood etc by just changing the Blade and dialling in a the higher appropriate speed for the motor.

Please remember that if you are going to cut steel on a wood bandsaw you should clean the saw of sawdust before cutting metal to prevent fires.

Ron

My wood vertical bandsaw ( a Woodfast 19" model of Chinese origin) has a two speed belt transmission and runs at 1246 or 2690 FPM ( 380 or 820 M/min)

Even the lower speed is much too fast for steel cutting which has a recommendation of around 100FPM or 30-40 M/min.

I overcame the problem by removing the original 2Hp single phase 1400rpm motor and replacing it with a second hand flange mount 3 Phase 4 pole 3 Hp 1440 rpm motor. 2nd hand 3 phase motors are available very cheaply on eBay in Australia. In retrospect a 6 pole motor that runs around 900 rpm would give even slower cutting speeds. Alternatively a smaller pulley on the motor may be possible which can be compensated for when cutting wood by setting the VFD to boost the speed

.

I then fitted a second hand Allen Bradley 1305 2.2 Kw VFD with the Control Panel removed. ( many VFD's allow you to remove the control panel and mount it externally on an extension cord). This particular Allen Bradley VFD is an older model, readily available 2nd hand fairly cheaply, and from my experience pretty bullet proof. Also there are many Chinese versions available on eBay. VFD's are available to run off single or three phase supply whichever suits your workshop.

VFD mounted on back of Bandsaw under table. Out of the way and out of the swarf.

The VFD Control panel was mounted on the front of the Bandsaw for ease of control. It is used to start, stop and adjust the speed of the saw. The control panel has a button for reversing the motor but for safety reasons this was locked out in the software. The VFD allows me to run the saw from 10 to 60 Hz (124 to 300FPM). A 6pole motor would have allowed speeds down to about 90 fpm

It will actually go up to 400Hz but this is not recommended for either the saw or the motor and has been limited in the programming of the VFD. The next photo shows the motor running at 10 Hz with plenty of torque to cut 1" steel.

I tested by cutting through 1" steel rod. Progress was remarkably good, faster than I had imagined and the band saw never lacked power. VFD's have the capacity to boost current and hence power at low speeds. The bandsaw blade I used was a Starrett Carbon Steel 1/2" 14tpi Raker Set and it produced a very smooth cut even used without coolant.

I was worried that slowing the motor to 10 Hz would also slow the motor cooling fan, causing it to overheat. My tests so far seem to indicate that there is no problem. The power required to cut the 1" steel rod was so low that the 3 Hp motor didn't even get warm. Extended cutting may turn up a problem but I don't think it will be an issue for the amount of steel I cut.

The beauty of the system is that the saw will still cut brass, aluminium and wood etc by just changing the Blade and dialling in a the higher appropriate speed for the motor.

Please remember that if you are going to cut steel on a wood bandsaw you should clean the saw of sawdust before cutting metal to prevent fires.

Ron